How you can avoid costly turbine failures and maximize uptime

Steam turbine filtration: Maintaining turbine oil instead of changing it

How you can avoid costly turbine failures and maximize uptime

Steam turbine filtration: Maintaining turbine oil instead of changing it

Challenge

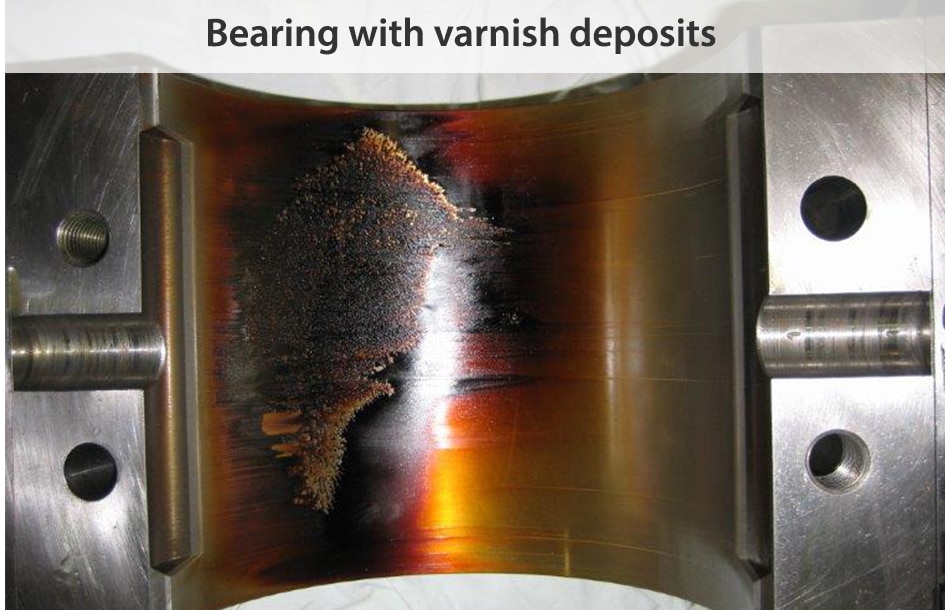

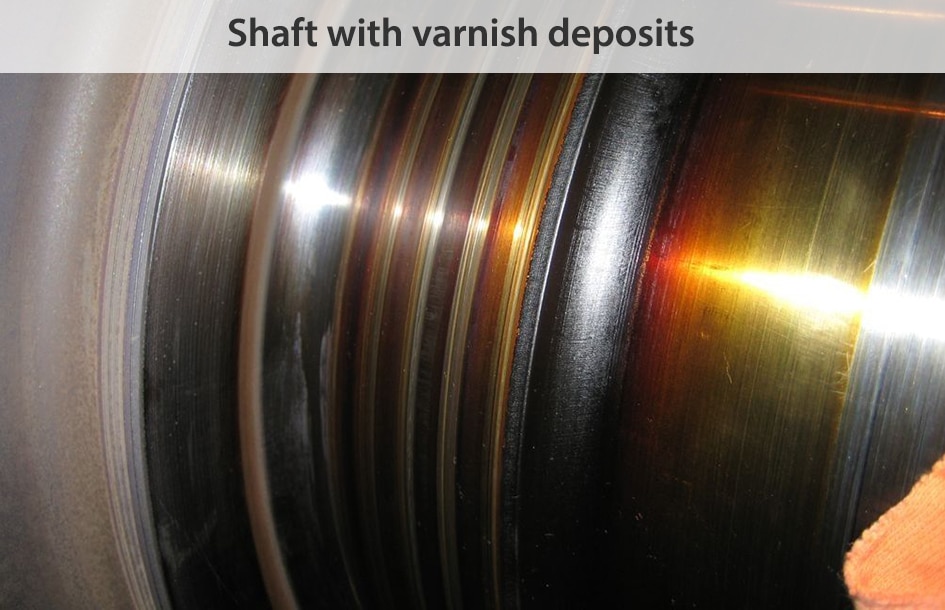

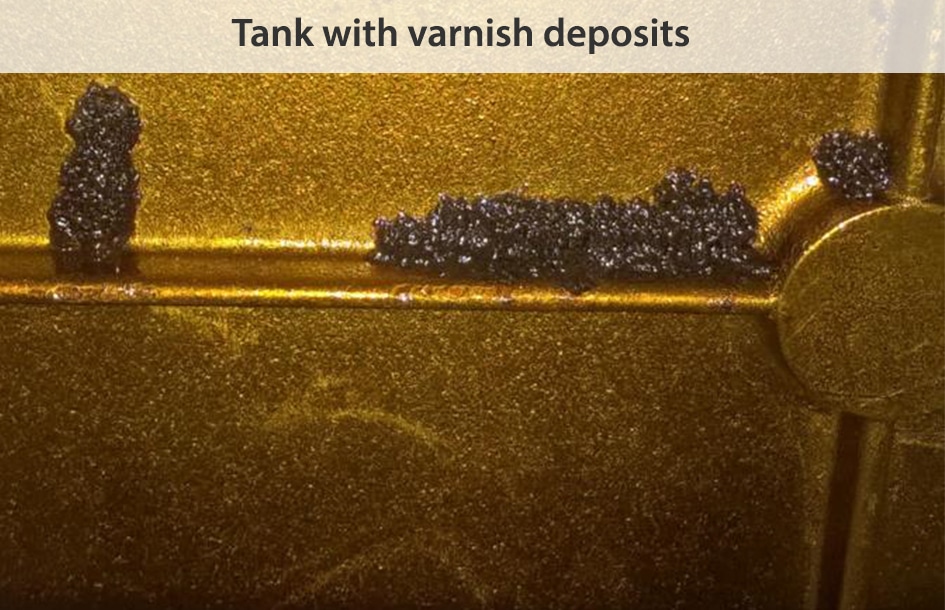

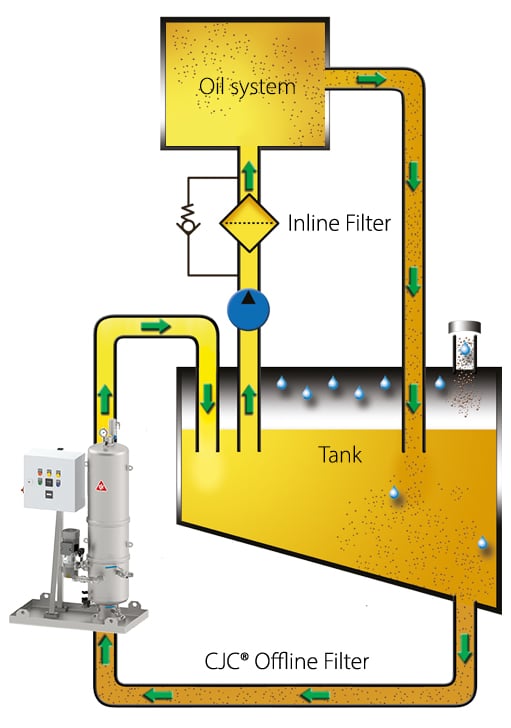

Lubrication systems and hydraulic control systems of steam turbines are exposed to a high risk of water ingress. Hot water vapor entering through the labyrinth seals and condensation due to temperature fluctuations increase the water content in the oil and the formation of lubricant-water emulsions is possible. Water and wear particles cause the lubricant to age rapidly (oil degradation, loss of additives), resulting in deposits. Damage and outages are the result and cause interruptions in power generation, which can result in contractual penalties.

With the central lubricating oil supply, all lubrication points and the hydraulic controllers are lubricated with the same lubricant. Due to the tight tolerances in the highly sensitive and complex hydraulic system, the lubricant must be as clean, dry and free of oxidation products as possible. Changing the large-volume oil fillings is time-consuming and expensive.

In a separate hydraulic control system, fire-resistant hydraulic fluids (typically phosphoric acid esters, HFD fluids, soy-based oils) are often used. However, when contaminated with water, ester-based fluids decompose by hydrolysis. The molecules split into their original alcohol and acid components, rendering the fluid unusable.

Damages and consequences of contaminated and prematurely ageing turbine oil

Your solution: efficient steam turbine filtration

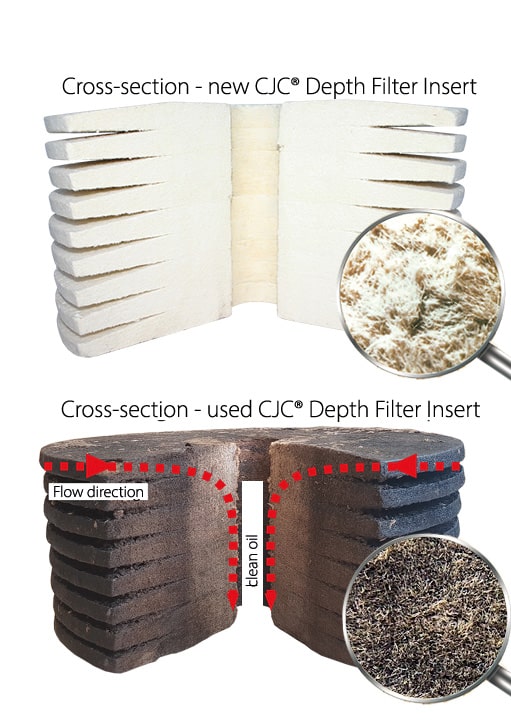

Efficient steam turbine filtration means continuously removing water, oxidation residues (varnish, acids) and particles from the turbine oil (24/7). Because the fact is, only with permanently dry and clean turbine oil you …

Less oil consumption

Less maintenance

Higher reliability

Better use of resources

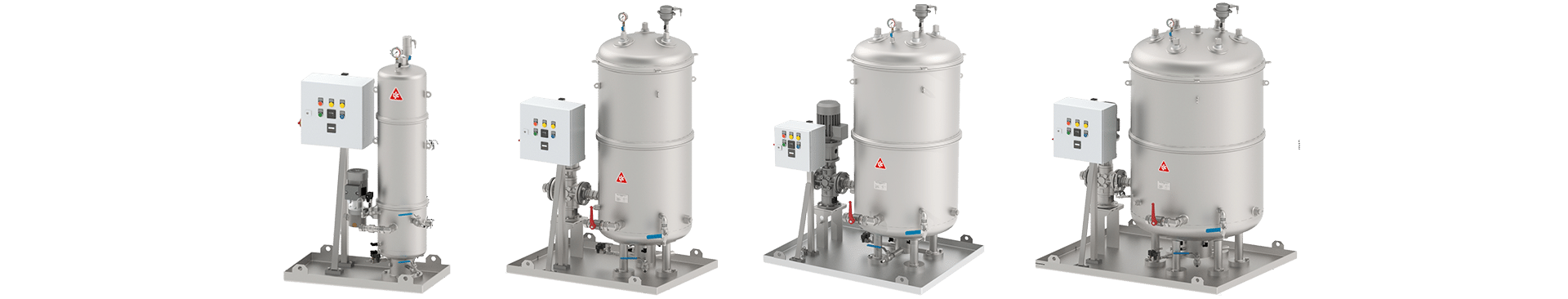

CJC® Steam Turbine Filters for efficient cleaning and maintenance of turbine oil

The water content in your turbine oil keeps rising rapidly, quickly reaches high oxidation rates and acid numbers and/or is contaminated with solids? Do you have to replace or clean bearings, valves, heat exchangers and pressure filters frequently due to deposits? Then the CJC® Steam Turbine Filter is exactly the right solution for your steam turbine. It ensures maximum oil cleanliness in the shortest possible time — optionally documentable via our CJC® Condition Monitoring Systems. Extremely high filter capacities and separation performance make it a safe and cost-optimized solution.

Contact your regional salesperson now

Let’s talk: about your steam turbine, your turbine oil and the specific challenges. We filter each oil. Whether you use mineral oils, synthetic fluids or fire-resistant hydraulic fluids. Together with you we maximize the service life of your lubricants and oil-lubricated components.

Receive a personal consultation and a non-binding offer for a CJC® Steam Turbine Filter for efficient oil maintenance.

.

Write or call us.

That say our customers

“We have been advocating these secondary CJC® Offline Filters for 2 years. The filters have value for varnish removal to keep in-service oil clean, which is a major concern of us reliability engineers

The also enable fast oil system cleanup after construction, something our project and operations people highly value […] this unit will greatly reduce clean up time and/or eliminate the need to hire expensive rental equipment and contractors to do oil cleanup. The saved time during commissioning a new turbine was reason enough for our purchase decision.”

„The CJC® Steam Turbine Filter has produced astonishing results. It is an ancillary installation in an independent circuit with a rapid pay back because we have less mechanical breakdowns and less oil and filter changes.

We have now installed another 2 CJC® Offline Filters for the 400 litres hydraulic systems in order to reduce maintenance work saving time and money. I can

highly recommend CJC® Offline Filters.“

“The turbine lubricating oil in my steam turbines #2 and #3 has never been so clean.”

“We are extremely satisfied with the performance. The maintenance of the oil in the offline flow is extremely effective for our steam turbine. The lubricating properties are preserved in the long term by removing the impurities (particles, water). We will also install a CJC® oil maintenance system on each of our two gas turbines to remove oxidation products and wear particles that are not retained by the system filters.”