How you can drain rainwater from catch basins of transformer stations —

automated, documented and environmentally safe

SIPP Node: Your solution for transformer pit management 4.0

How you can drain rainwater from catch basins of transformer stations —

automated, documented and environmentally safe

SIPP Node: Your solution for transformer pit management 4.0

SIPP Node

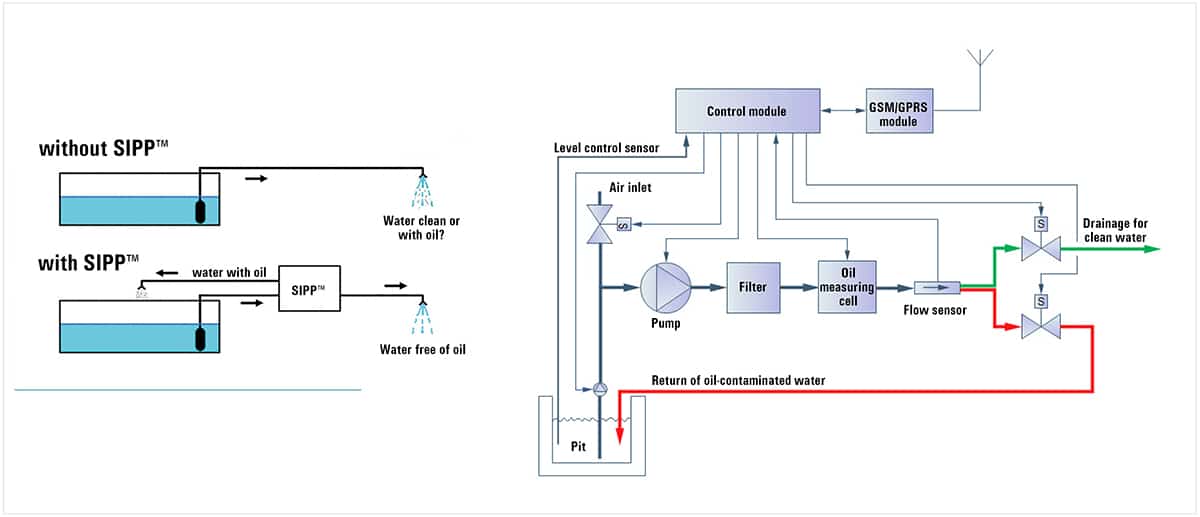

SIPP Node ensures the automatic, environmentally safe, quality-controlled and documented drainage of water from catch basins of transformer stations — without the need for on-site personnel. The top priority is compliance with legal guidelines regarding the residual oil content when discharging water into the environment. The SIPP Node ensures sufficient oil capacity in the catch basin — at all times. Economically and ecologically convincing, already > 20,000 derivatives confirm the success.

How you benefit from installing a SIPP Node

With your SIPP Node, you automate processes and enable your team more time for more complex core tasks.

Product Benefits — SIPP Node

Optimally customizable

You can optimally adapt the SIPP Node to any catch basin in three sizes with different capacities and individually configurable messages.

Secure & communicative

The SIPP Node communicates via GPRS with a fixed IP address and SSL encryption. You have access to all status and process data at any time.

Accurate & environmentally safe

With a sampling frequency accurate to the second and a measurement accuracy of +/- 1 ppm, the SIPP Node detects the tiniest oil particles in the water of the catch basin.

Tested & proven

DIBt, the German Institute for Construction Technology and TÜV Rheinland approves the SIPP Node. But the SIPP Node is also proven and renowned worldwide.

Product Features — SIPP Node

The SIPP Node has an integrated sensor for real-time monitoring of the current water level in the catch basin of your transformer station. When the water level you have pre-defined is reached, the discharge begins. The SIPP Node directs the water from the catchment basin to its measuring cell, which detects the oil content in the water. The filter upstream of the measuring cell (filtration degree 10 μm) removes solids and impurities from the water and thus prevents the results from being affected. With a measuring accuracy of +/- 1 ppm, the measuring cell uses infrared light to determine the oil content in the water every second. Subsequently, the control module regulates the discharge or, if necessary, the return of the water into the catch basin. The SIPP Node discharges only unpolluted water into the environment, which does not exceed the maximum permissible oil content (e.g. max. 5 ppm for transformer stations and discharge into the sewer system).

Customer cases

Real-world reports show the savings and benefits operators have achieved using their SIPP Nodes.

Write or call your personal contact person now

Do you have questions about the SIPP Node and would you like to find out how you can integrate the system into your transformer station and IT infrastructure? Would you like to find out more about the building authority approval and how the environmental requirements are met in order to discharge the water into the sewage system or into soakaways? I would be happy to advise you individually as your personal contact. Together, we automate your processes and release internal resources. Just call or e-mail.

In close cooperation with