particle counter with water-in-oil sensor

The particle counter with water-in-oil sensor and temperature sensor enables continuous monitoring of the oil cleanliness and the acquisition of exact oil condition data in real time. The particle counter and oil contamination monitor CJC® OCM15 installed at a CJC® Oil Care System in an offline circuit are the optimum combination for proactive and condition-based maintenance.

ADVANTAGESDUE TO MONITORING OF OIL CLEANLINESS

- Maximum wear protection and maximum oil service life through efficient oil care and continuous monitoring of oil cleanliness (particle content, oil moisture, oil temperature) – always clean and dry oil

- Increased machine reliability and lifetime as well as improved process stability

- Data logging in real time as an early alert system for application- and machine-specific limit values

- Individual and transparent data interpretation enables

- to detect harmful influences and deviations from the normal state as early as possible and minimize their effects

- Plannable, calculable maintenance instead of unplanned, cost-intensive failures

- High-quality sensors ensure exact and reliable values (particle content, oil moisture, oil temperature)

- Online-Monitoring as Best-Practice-Method optimizes the oil analysis program and management

- High savings and accelerated return on investment

FEATURES — PARTICLE COUNTER WITH WATER-IN-OIL SENSOR

The integrated CJC® Sensor Technology for continuous oil contamination and condition monitoring includes:

- Particle counter to measure the particle content in the oil (ISO 4406)

- Water-in-oil- sensor to measure oil moisture (rF in %)

- Temperature sensor to measure oil temperature

The particle counter and oil contamination monitor CJC® OCM15 is installed in combination with a CJC® Oil Care System in the off-line circuit Due to the constant volume flow and stable low-pressure conditions, exact values can be measured, independent from viscosity, air entrainment and oil condition.

The CJC® OCM15 is installed upstream of the CJC® Oil Care System. Quick and easy retrofit is possible.

The CJC® Oil Care System continuously removes particle, water and oil degradation products (varnish, oxidation residues, acids) from the oil. The highest oil cleanliness levels are achieved in the shortest time, independent from the various industries.

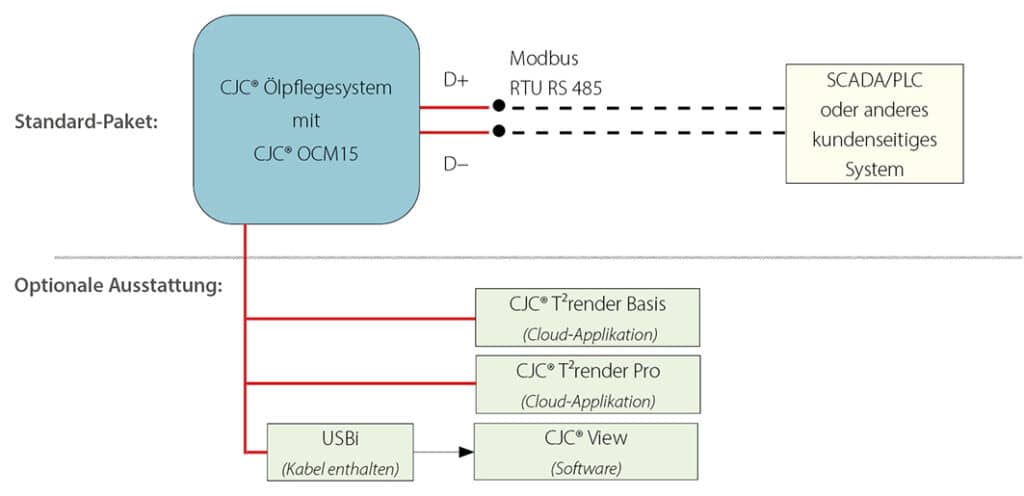

DATATRANSFER & MONITORING

The CJC® OCM15 is delivered with integrated RS 485 Modbus RTU protocol as the interface for fast communication with SCADA/PLC or other custom expert systems.

Optional:

- Data transfer via USBi and monitoring via CJC® View Software

- Data transfer and monitoring via cloud-application CJC® T2render

| Technical data | ||||

|---|---|---|---|---|

| Particle counter and oil contamination monitor CJC® OCM15 |

||||

| Oil types |

Mineral oils and petroleum-based fluids

|

|||

| Viscosity range | < 1.000 cSt | |||

| Oil temperature, max. | 80 °C | |||

| OIL CONDITION SENSORS | ||||

| Oil condition sensors | Particle counter Water-in-oil sensor (oil moisture in rF in %) * Temperature sensor (oil temperature in °C) |

|||

| Particle sizes |

> 4, 6, 14, 21, 25, 38, 50, 70 up to 250 µm | |||

| Classification of particles |

ISO 4406 / NAS 1638 / SAE AS 4059 | |||

| Calibration |

according to ISO 11171 | |||

| Repeatability |

0,5 ISO codes (min. conzentration ISO MTD 2,8 mg/l, max. ISO code=24) |

|||

| Sampling intervals |

individual adjustable | |||

| Display |

Yes | |||

| ELECTRICAL CONNECTION | ||||

| Motor voltage | DC / AC (incl. motor protection switch) |

|||