How you can reduce OPEX and extend the service life of your energy generation plants

Oil maintenance in power plants and transformer stations: CJC® Oil Care Systems for maximum oil cleanliness

How you can reduce OPEX and extend the service life of your energy generation plants

Oil maintenance in power plants and transformer stations: CJC® Oil Care Systems for maximum oil cleanliness

Oil maintenance in power plants and transformer stations is extremely important if you …

Oil care in power plants and transformer stations

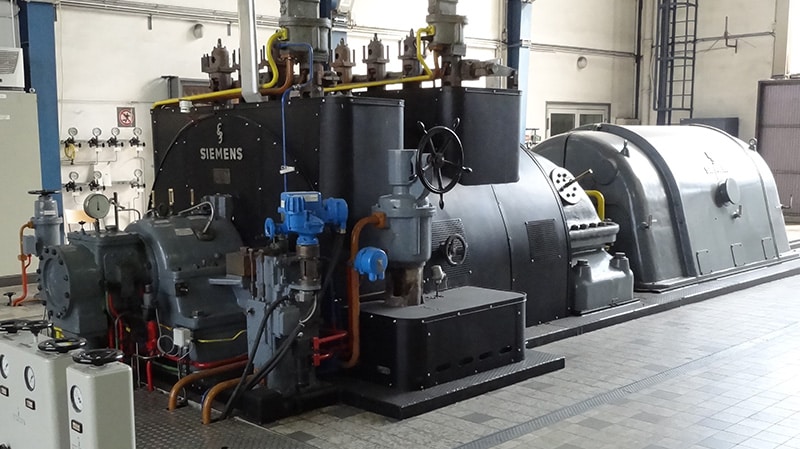

Discover your various benefits and enormous savings potential. Whether for turbines, transformers, gas engines, emergency power systems, feed pumps or coal mills and coal crushers, investing in efficient oil maintenance systems pays off — in over 75 % of the cases, CJC® Oil Care Systems amortize within the first year of operation.

That say our customers

“The CJC® VRU has reduced the MPC value to low, stable and controlled levels, giving us peace of mind and the security of having clean, varnish-free oil. In addition, since the CJC® VRU Filter was put into operation, we have abserved fewer pressure filter changes and a reduction in system component failures, which has resulted in financial savings.”

„In addition to the good advice that we have always received, I positively value the effectiveness of the treatment in the short term (6 months), allowing us to prolong the lifetime of the oil, with the corresponding cost savings and reduction of the waste generated.“

„The CJC® Steam Turbine Filter has produced astonishing results. It is an ancillary installation in an independent circuit with a rapid pay back because we have less mechanical breakdowns and less oil and filter changes. We have now installed another 2 CJC® Offline Filters for the 400 litres hydraulic systems in order to reduce maintenance work saving time and money. I can highly recommend CJC® Offline Filters.“

„The laboratory reports have confirmed our first-hand impression after the visual inspection: From day one, the effect was evident (see photos of the oil samples). Our control valves work precisely and reliable again, and the oil quality meet the requirements. In a month, we treated the hydraulic oil in 2 tanks with the CJC® Filter and reached the same results. Components such as flow-blocks and pumps are now preserved more effectively against wear.“

“We have been advocating these secondary CJC® Offline Filters for 2 years. The filters have value for varnish removal to keep in-service oil clean, which is a major concern of us reliability engineers

The also enable fast oil system cleanup after construction, something our project and operations people highly value […] this unit will greatly reduce clean up time and/or eliminate the need to hire expensive rental equipment and contractors to do oil cleanup. The saved time during commissioning a new turbine was reason enough for our purchase decision.”

“Before the installation of the CJC® Gas Turbine Filter,we were experiencing failed gas valve servo(s) just about every start. We tried other varnish removal units, but we were not getting the results we wanted. Within a short time after we installed the CJC® Gas Turbine Filter, the varnish problems we were experiencing, diminished. Our varnish levels dropped to very low levels and we have not experienced servo problems since. We are very satisfied with the results and now have again the confidence that the gas turbine will operate reliably as soon as the start button is pushed.”

“We are extremely satisfied with the performance. The maintenance of the oil in the offline flow is extremely effective for our steam turbine. The lubricating properties are preserved in the long term by removing the impurities (particles, water). We will also install a CJC® oil maintenance system on each of our two gas turbines to remove oxidation products and wear particles that are not retained by the system filters.”

“The CJC® Filter Separator is not only very easy to operate and extremely low-maintenance, it also allows us to completely dispense with the use of the centrifuge. I am more than satisfied with the results.”

„After installing the CJC® Oil Filter System on our control oil systems, we have seen Varnish Potential numbers drop to single digit values. The CJC® Filter System has performed well and is reasonably priced for the application, and works excellently.“

„I am very pleased with the results, we have obtained with the new CJC® Oil Care Systems. The approach of analysing the results for G3 before purchasing for the other eight units, made the decision easy for our controller.“

„The turbine oil on my steam turbine #2 and #3 has never been cleaner.“

Contact your regional contact now

Let’s talk about your turbines, gas engines, diesel storage tanks or transformers, the oil you use and the specific challenges you face. We filter each oil. Whether you use mineral oils, synthetic fluids or fire-resistant hydraulic fluids. We maximizie together wit you the lifetime of your lubricants and fuels, and of the oil-lubed components.

Receive a personal consultation and a non-binding offer for a CJC® Oil Care System for efficient oil maintenance in power stations and transformer stations.

Write or call us.