How you can save lubricants, energy and CO2 emissions and improve CII approx. by 2 %

Lubricant filtration for marine diesel engines and gas engines: Use CJC® Lube Oil Filter instead of centrifuges

How you can save lubricants, energy and CO2 emissions and improve CII approx. by 2 %

Lubricant filtration for marine diesel engines and gas engines: Use CJC® Lube Oil Filter instead of centrifuges

Lubricant filtration for marine diesel engines and gas engines with CJC® is exactly what you need if you …

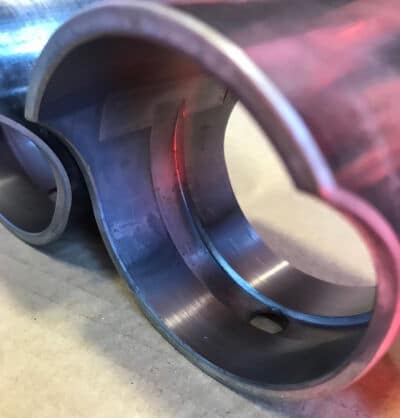

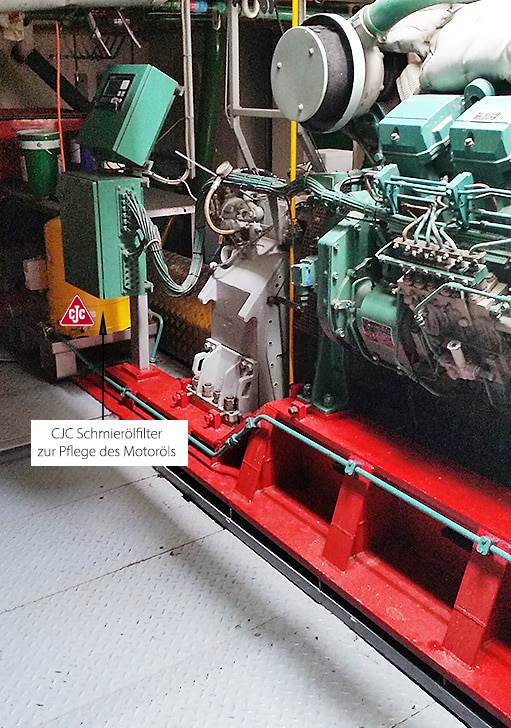

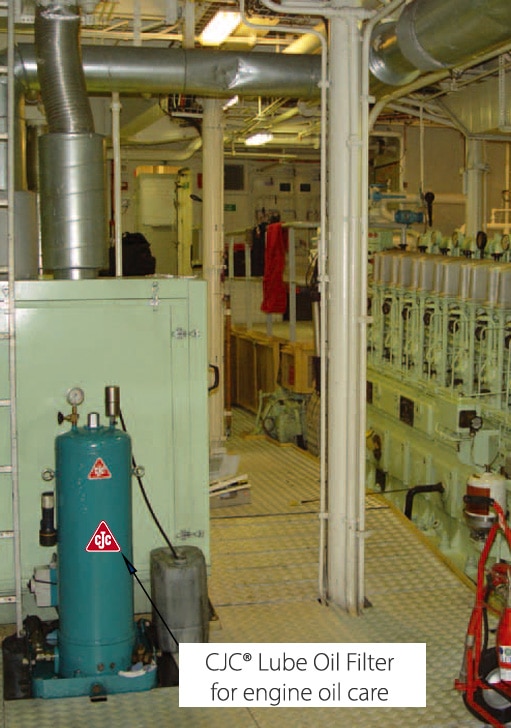

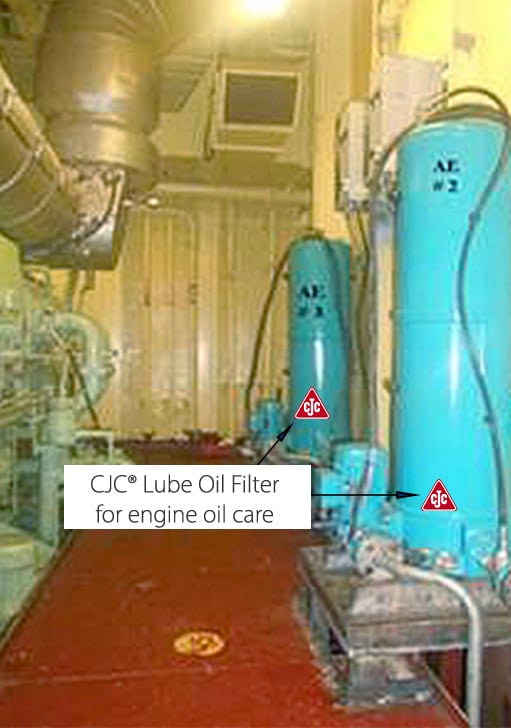

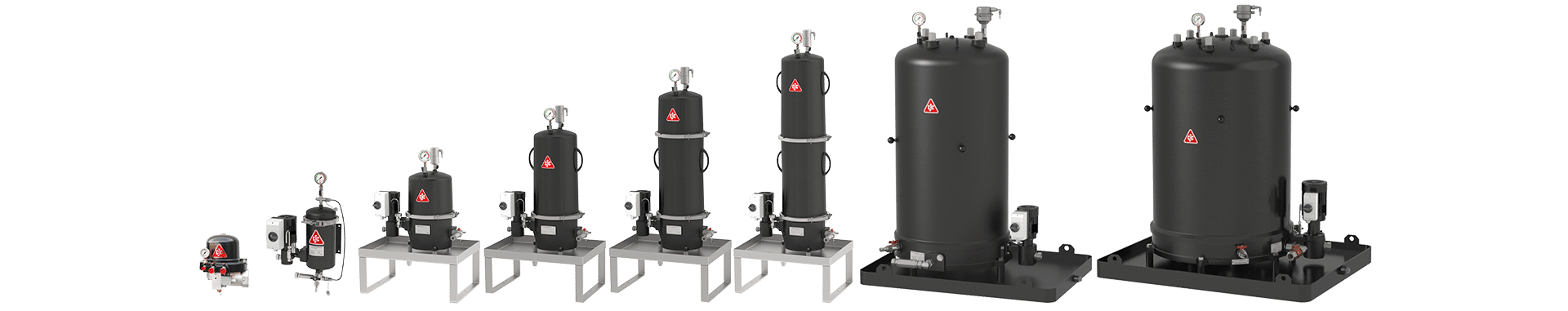

The solution for your marine diesel engines and gas engines: CJC® Marine Lube Oil Filter in the off-line circuit. Achieve the highest oil cleanliness for maximum protection of the lube oil, additives and engine — quickly, efficiently and cost-effectively.

The challenge: contaminated and quickly ageing lubricant

The lubricant of marine diesel engines and gas engines is loaded differently, depending on whether it is a four-stroke or two-stroke engine. In principle, however, the entry of impurities into the lubricant is unavoidable:

particles, water and blow-by gases enter the lubrication system as a result of combustion and wear processes, environmental conditions (temperature changes, climate zones, etc.) and during repairs and cleanings. These contaminants accelerate the oil oxidation and lead to early additive consumption — even with high-quality synthetic lubricants.

Damage and consequences caused by contaminated and rapidly ageing lubricant

The consequences have a serious impact on operational safety, availability, cost-effectiveness and sustainability of ship operations.

The conventional method

To ensure the reliable operation of the marine diesel engine, the crew regularly checks the condition of the lubricant. When a critical value is reached, they partially replace the lubricant or change the oil completely.

However, this does not reduce the load on the lubricant. On the one hand, the newly filled-in oil contaminates within the shortest time due to deposits and dilution with dirty residual oil. On the other hand, impurities, oxidative processes and acids unhindered strain the lubricating properties and the long-term effect of additives, which shortens the service life of the oil filling.

Finally, the frequent refill and change intervals result in high oil consumption, cost money and pollute the environment. An efficient lubricant filtration is more ecological and economical.

Your solution: Replace centrifuges with CJC® Marine Lube Oil Filters

Due to the enormous savings potential in terms of operating and energy costs, and the lower lubricating oil losses, the CJC® Marine Lube Oil Filter amortizes in 75 % of all cases within the first year of operation — despite the additional installation costs when retrofitting and replacing the centrifuge.

CJC® Marine Lube Oil Filter are

easier to install and operate

CJC® Marine Lube Oil Filter ensure

the highest oil cleanliness

CJC® Marine Lube Oil Filter enable

enormous savings

Briefly explained in our video

CJC® Lube Oil Filter for the care and filtration of lubricants

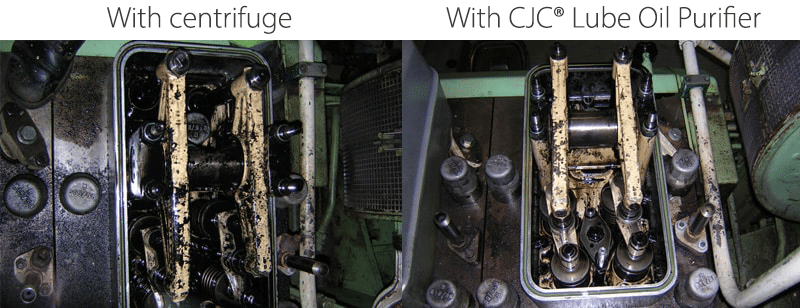

CJC® Lube Oil Filters ensure maximum oil cleanliness — they easily exceed the recommended cleanliness classes of the engine manufacturers. Achieve fast, long-lasting and cost-optimized maximum protection for your oil filling and marine diesel engines / gas engines. Rely on world-renowned solutions with documented field results in engine lube oil filtration for over 73 years.

Your benefits from lubricant filtration with CJC®

Efficient lubricant care means continuously removing particles, water, oxidation residues and acids from the lubricant of your marine diesel engine (24/7). The fact is, only with permanently clean and dry lubricant you …

Less oil consumption

Less maintenance

Higher engine reliability

Better protection of resources

That say our customers

“The CJC® Lube Oil Filters […] reliable and efficient alternative […]. […] engine lube oil properties were maintained in specified areas (viscosity, additives, TBN, particle and water content) or improved (e. g. dispersancy). The high savings potential regarding lube oil losses, energy costs and CO2 emissions are convincing […].“

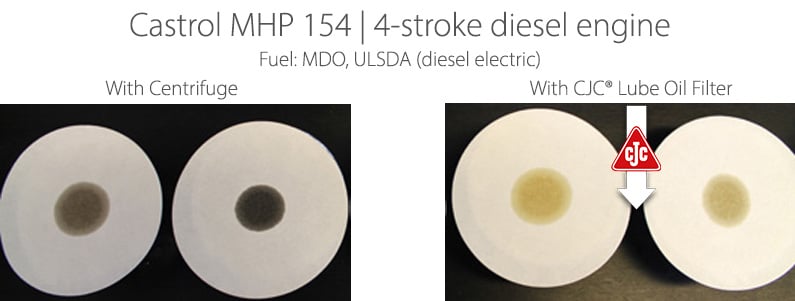

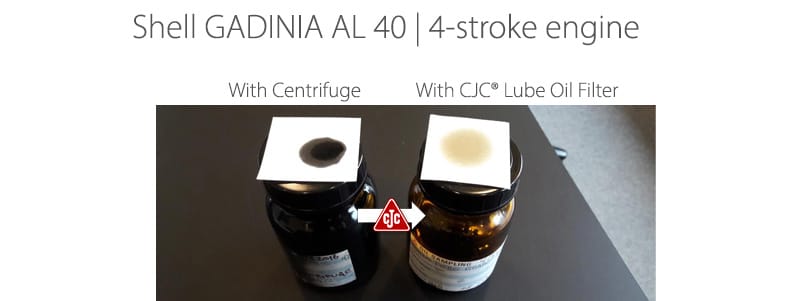

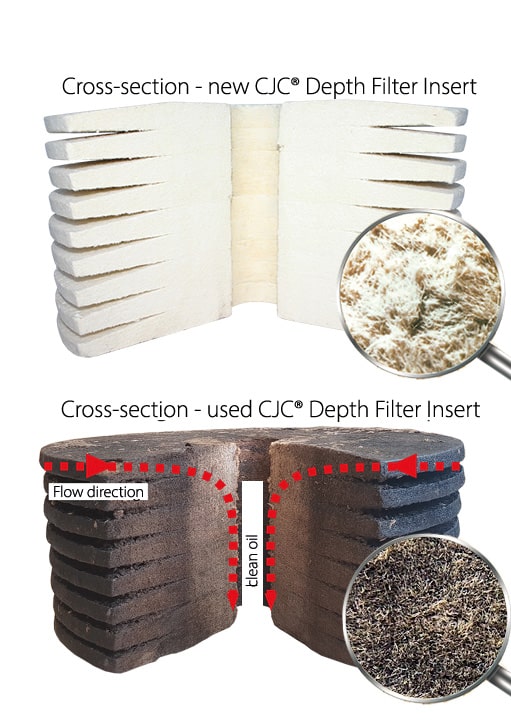

“Our experiences with operation and filter replacement are excellent! We have weight the used filter insert. The drained net weight among 49.2 kg – i. e. in total, the CJC® Oil Filter >removed 38 kg dirt. The engine lube oil on the test membrane is brown and not black anymore! The CJC® Oil Filter is really efficient :)!”

“We have only had positive experiences with the CJC® Oil Filters. The quality of the oil is as good as before, in every respect actually even better. The appearance of the oil changed from dark to light and corresponds to that of new oil. We save man-hours and chemicals used to clean the centrifuge and have less clutter in the engine room. Also, no sludge is produced during filtration. The centrifuge feeds out every hour. Displacement water/rinsing water is used for cleaning. The oil loss caused by centrifugation contaminates the water. The resulting sludge consists of about 0.2 liters of oil (oil loss) and about 2.5 liters of water (cleaning) and is discharged directly into the sludge tank. With 8,700 outlets per year, this is about 1,740 liters of oil and about 21,750 liters of water. The costs for the disposal of this amount of sludge amount to approx. 2,013 EUR/year. In addition, lubricating oil consumption is reduced. This is because the oil loss that occurs during centrifugation and in the event of failures or malfunctions amounts to about 2,500 to 3,000 liters per year. At a price of 1.34 EUR per litre, this brings us a saving of about 3,356 to 4,027 EUR/year. All around a good investment and if we do not switch to electric drive, we will definitely install oil filters on the DG1 and DG2 engines as well.”

“I can only recommend the installation of CJC® Lube Oil Filters — it’s hard to believe how much dirt a single cartridge can hold.”

“I already had a filter for diesel filtering on the old ship (also Shenandoah) and was always satisfied with it. For my new building I really wanted to have a CJC® System again. For even better engine care, I also decided to clean the lubricating oil with a CJC® Fine Filter!”

“The filter system and the oil analyses fully convinced me! The oil was still bright and clear after > 700 running hours. The injection nozzles are also much cleaner! The improved oil cleanliness not only extends the service life, but also protects the engine components even better against wear and contamination/deposits!”

“The difference between oil condition before and after installation of the CJC® Lube Oil Filter is clearly visible — the color of the oil is again a bit more golden. The biggest challenge with centrifuges is that they feed out a lot of oil sludge ( sludge). Although the sludge consists of 90-95% water, the disposal of this sludge as well as the operation of the centrifuge is very expensive.”

“I recommend leaving our lubricating oil centrifuges on land and purchasing more CJC® filters for the remaining engines. The advantage of this is that we no longer need to use the centrifuges and thus have considerable cost and time savings. According to a rough estimate, the use of these two lubricating oil centrifuges produces 280 m³ of sludge per year (8 l of sludge per change, 4 changes per hour). Part of the sludge is made of lubricating oil, which means that we can also significantly reduce lubricating oil consumption. The disposal of the sludge also incurs high costs — for spare parts for the incinerator and the bilge water system, diesel for the combustion process — which we are now saving. Not to mention the positive impact on the environment — as an extra bonus.”

Technical inspector:

“I have worked as a senior engineer on ships for many years and have had good experience with CJC® filters, so I was not surprised by the good result. We will now also install similar CJC® filters on the other 3 engines of the Bourbon Mistral, as well as on the 4 engines of the sister ship M/S Bourbon Monsoon.”

“It all looks promising. If the service life of the filter cartridge is one year, the running costs are significantly lower than with the centrifuge. I would also like to mention that maintenance times will be reduced. I think the photos speak for themselves…”

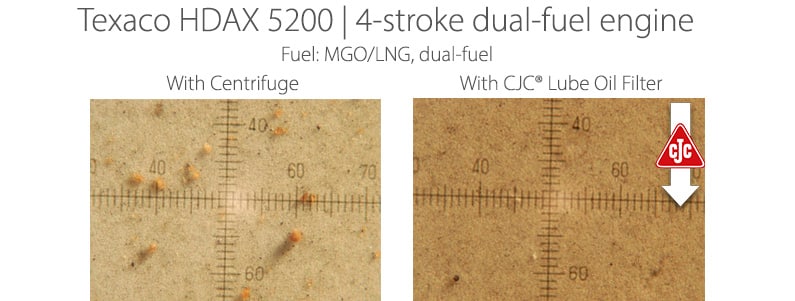

“In conjunction with the results obtained, it becomes clear that the use of a CJC® Lube Oil Filter extends the service life of the oil. Texaco’s analyses showed a reduction in iron content from 16 ppm to 5 ppm. The service life of the fine filter insert was shorter than expected, but this was due to the low utilization of the engine and the resulting high soot load.”

Contact your maritime technical salesperson now

Let’s talk: about your marine diesel engines / gas engines, your lubricants and the specific challenges. We filter every engine oil – whether two-stroke or four-stroke engine oil, whether main or auxiliary engines and whether you use LNG, MDO, MGO, distillates, blended or residual fuel grades, dual fual or heavy fuel oil. Together with you, we maximize the service life of the oil filling and engines.

eceive a personal consultation and a non-binding offer about a CJC® Marine Lube Oil Filter for the efficient care, drying and filtration of your lubricants.

Write to me or give me a call.