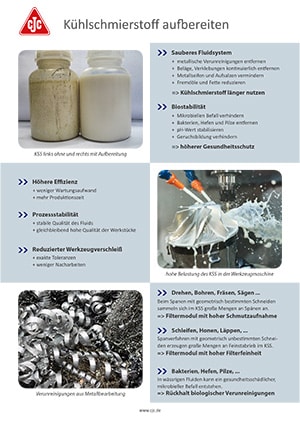

USE THE COOLANT AS LONG AS POSSIBLE

CLEAN FLUID SYSTEM BY CJC® COOLING LUBRICANT FILTER

+ Remove metallic impurities

+ Remove deposits and sticky residues continuously

+ Reduce metal soaps and salting

+ Reduce foreign oils and grease

HIGHER HEALTH PROTECTION

HIGH BIOSTABILITY BY CJC® KSS FILTER

+ Avoid microbial growth

+ Remove bacteria, yeasts and fungi

+ stabilize pH

+ Prevent odour formation

USE THE COOLANT AS LONG AS POSSIBLE

CLEAN FLUID SYSTEM BY CJC® COOLING LUBRICANT FILTER

+ Remove metallic impurities

+ Remove deposits and sticky residues continuously

+ Reduce metal soaps and salting

+ Reduce foreign oils and grease

HIGHER HEALTH PROTECTION

HIGH BIOSTABILITY BY CJC® KSS FILTER

+ Avoid microbial growth

+ Remove bacteria, yeasts and fungi

+ stabilize pH

+ Prevent odour formation

HIGHER EFFICIENCY

OPTIMIZE RETURN ON INVESTMENT WITH CJC® COOLING LUBRICANT FILTER

+ less maintenance

+ more production time

PROCESS STABILITY

INCREASE OUTPUT WITH CJC® COOLING LUBRICANT FILTER

+ stable quality of the fluid

+ consistently high quality of the workpieces

REDUCED TOOL WEAR

GENERATE SAVINGS WITH CJC® COOLING LUBRICANT FILTER

+ exact tolerances

+ less rework

HIGHER EFFICIENCY

OPTIMIZE RETURN ON INVESTMENT WITH CJC® COOLING LUBRICANT FILTER

+ less maintenance

+ more production time

PROCESS STABILITY

INCREASE OUTPUT WITH CJC® COOLING LUBRICANT FILTER

+ stable quality of the fluid

+ consistently high quality of the workpieces

REDUCED TOOL WEAR

GENERATE SAVINGS WITH CJC® COOLING LUBRICANT FILTER

+ exact tolerances

+ less rework

TURNING, DRILLING, CUTTING, SAWING …

COOLING LUBRICANT FILTER WITH HIGH DIRT HOLDING CAPACITY CRUCIAL

When chipping with geometrically determined cutting edges

large amounts of chips accumulate in the cooling lubricant.

GRINDING, HONING, LAPPING …

COOLING LUBRICANT FILTER WITH HIGH FILTRATION DEGREE IMPORTANT

Chipping process with geometrically indeterminate cutting edges

produce large amounts of fine rod rupee in the cooling lubricant.

BACTERIA, YEASTS, FUNGI …

RETAINING OF BIOLOGICAL IMPURITIES ESSENTIAL

In aqueous fluids, harmful microbial growth can occur.

TURNING, DRILLING, CUTTING, SAWING …

COOLING LUBRICANT FILTER WITH HIGH DIRT HOLDING CAPACITY CRUCIAL

When chipping with geometrically determined cutting edges

large amounts of chips accumulate in the cooling lubricant.

GRINDING, HONING, LAPPING …

COOLING LUBRICANT FILTER WITH HIGH FILTRATION DEGREE IMPORTANT

Chipping process with geometrically indeterminate cutting edges

produce large amounts of fine rod rupee in the cooling lubricant.

BACTERIA, YEASTS, FUNGI …

RETAINING OF BIOLOGICAL IMPURITIES ESSENTIAL

In aqueous fluids, harmful microbial growth can occur.

DEPTH FILTRATION

EXTRA LARGE SURFACE

+ high dirt absorption capacity

+ Retain finest particles and microbial impurities in the filter material

RELIABLE CLEANLINESS

MICROFILTER AND ABSOLUTE FILTER

+ Dirt retention consistently efficient

+ multiple extended service life of the cooling lubricant

Natural fibres

100% CELLULOSE

+ Filter material from renewable raw materials

+ Improve CO2footprint

DEPTH FILTRATION

EXTRA LARGE SURFACE

+ high dirt absorption capacity

+ Retain finest particles and microbial impurities in the filter material

RELIABLE CLEANLINESS

MICROFILTER AND ABSOLUTE FILTER

+ Dirt retention consistently efficient

+ multiple extended service life of the cooling lubricant

Natural fibres

100% CELLULOSE

+ Filter material from renewable raw materials

+ Improve CO2footprint

LOW-MAINTENANCE AND ROBUST

THE HIGHER THE FILTER CAPACITY, THE LONGER THE FILTER LIFE TIME

+ Simple installation on all tank sizes

+ Continuous operation with minimal maintenance expenditure

PROCESS INDEPENDENCY

COOLING LUBRICANT FILTRATION IN THE OFF-LINE CIRCUIT

+ mechanically separated from the fluid circuit

+ Filter change without production interruption

PREDICTIVE MAINTENANCE

IMPLEMENTATION INTO YOUR MONITORING PROGRAM

+ custom sensors

+ quick and easy to retrofit

LOW-MAINTENANCE AND ROBUST

THE HIGHER THE FILTER CAPACITY, THE LONGER THE FILTER LIFE TIME

+ Simple installation on all tank sizes

+ Continuous operation with minimal maintenance expenditure

PROCESS INDEPENDENCY

COOLING LUBRICANT FILTRATION IN THE OFF-LINE CIRCUIT

+ mechanically separated from the fluid circuit

+ Filter change without production interruption

PREDICTIVE MAINTENANCE

IMPLEMENTATION INTO YOUR MONITORING PROGRAM

+ custom sensors

+ quick and easy to retrofit

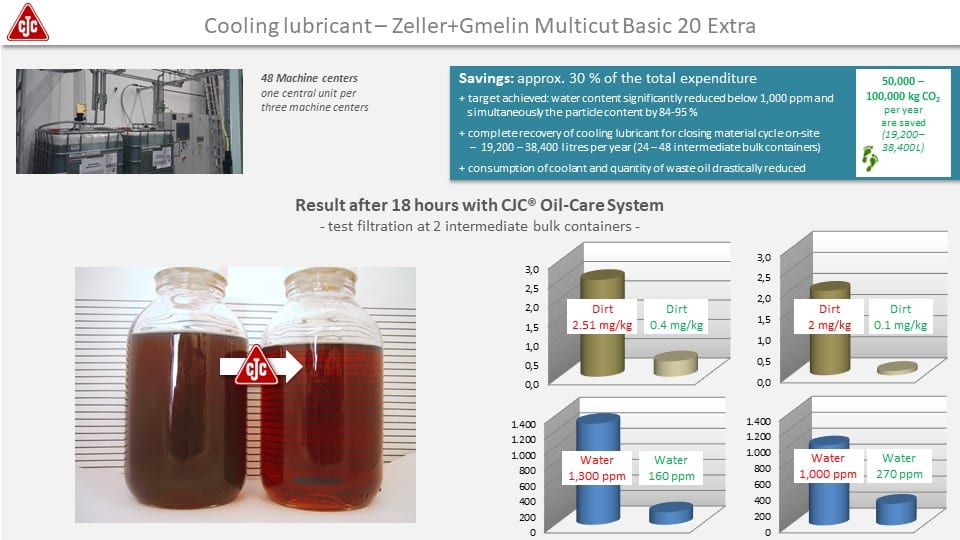

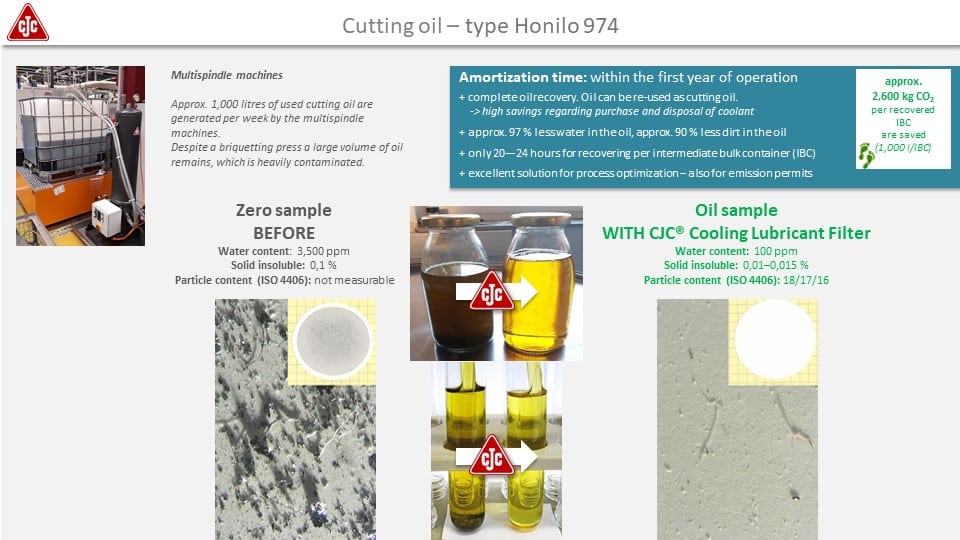

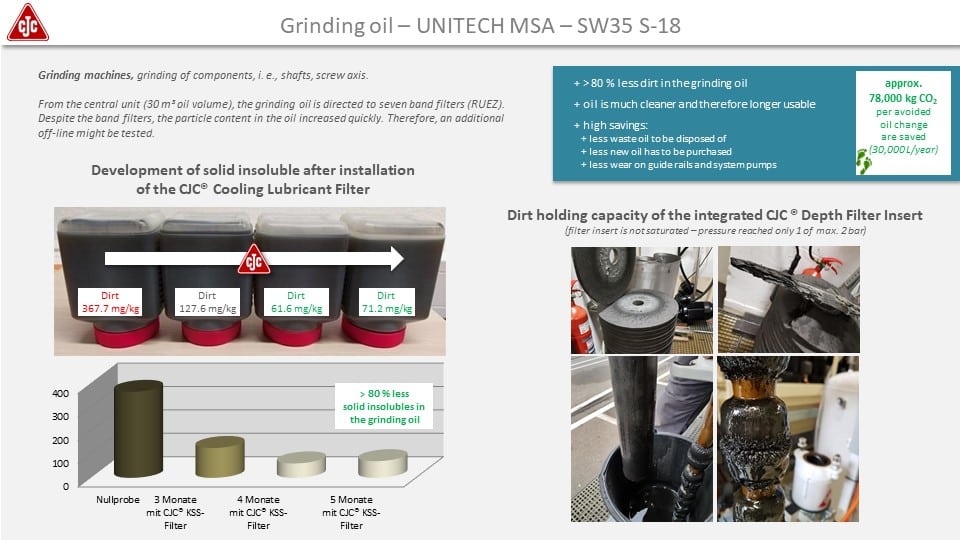

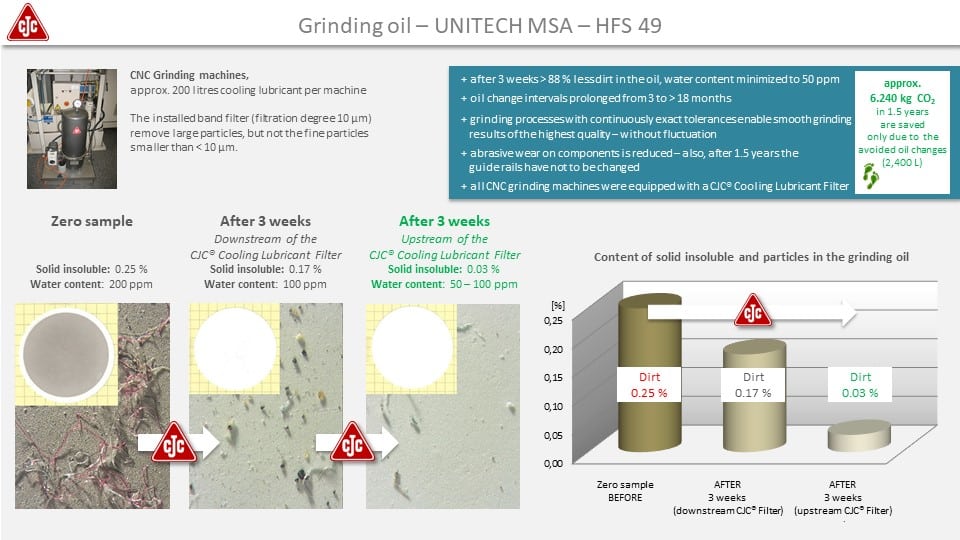

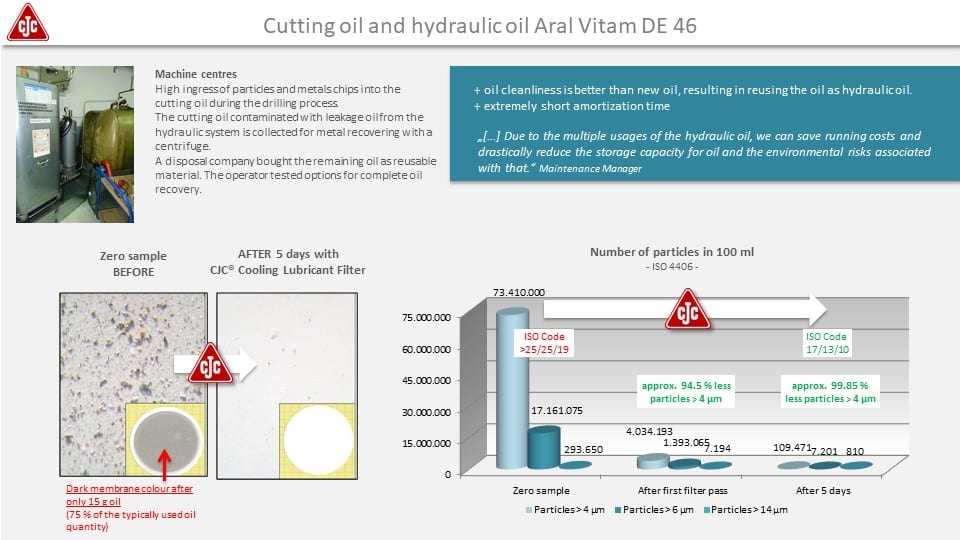

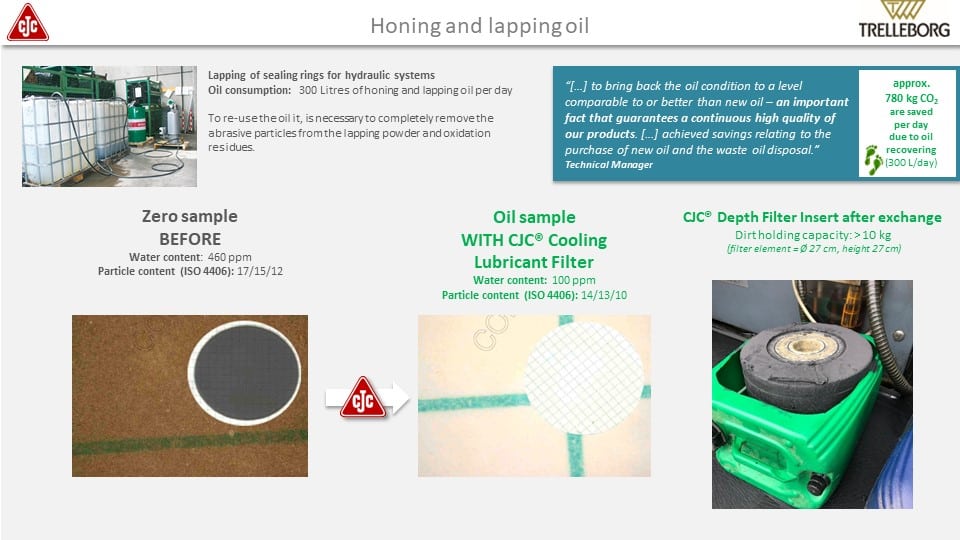

BEST PRACTICE EXAMPLES

BEST PRACTICE FOR COOLING LUBRICANT RECOVERY

See how machine tool operators benefit from the installation of the CJC® Cooling Lubricant Filter:

MAKE A TEST FILTRATION

Are you interested in test filtration with a CJC® Cooling Lubricant Filter?

Send us your desired date and a short message. Your regional technical will send an invitation for an online meeting.