How you can effortlessly maximize the availability of your gas turbine and avoid contractual penalties

Gas turbine filtration with CJC®: Your #1 for turbine oil

How you can effortlessly maximize the availability of your gas turbine and avoid contractual penalties

Gas turbine filtration with CJC®: Your #1 for turbine oil

Challenge

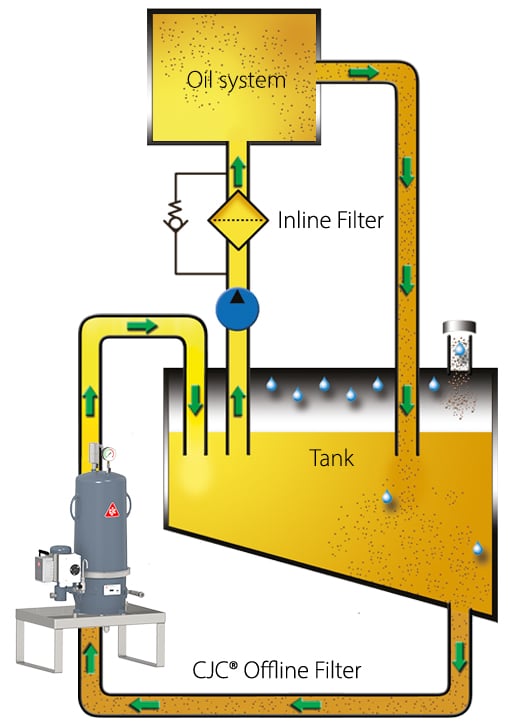

The lubricating oil system is one of the most critical systems in a gas turbine — faults here lead to some of the most serious damages and failures. High operating temperatures and speeds are the primary load factors for the turbine oil in the lubrication and control oil systems of the gas turbine.

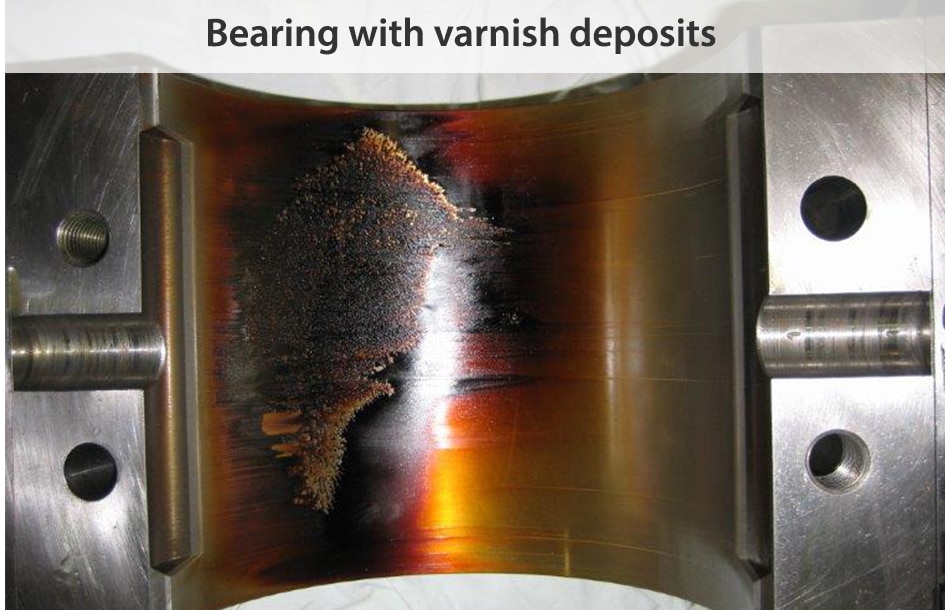

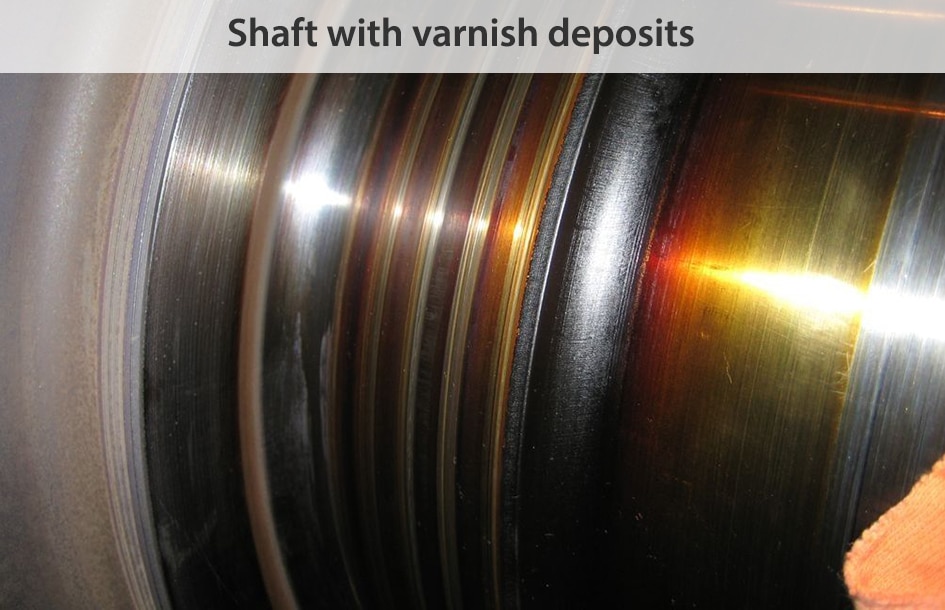

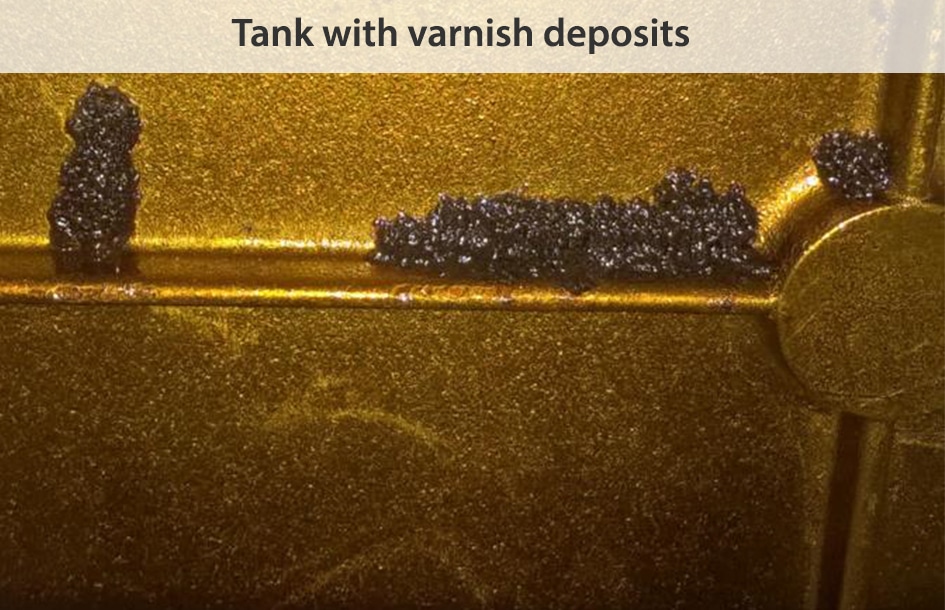

With the central lubricating oil supply, all lubrication points and control elements are lubricated with the same lubricating oil or come into contact with it: Bearings (plain, axial, main and pinion bearings), cooling system, pump and the sensitive control and valve technology. Contamination and varnish therefore lead to a high risk of wear and failure, deposits on all oil-lubricated components, reduced turbine performance and frequent oil changes with possibly costly system flushing as a result (high expense due to the large oil fillings).

In separate control oil systems, fire-resistant hydraulic fluids (typically phosphoric acid esters) are often used, which quickly become unstable and acidify when exposed to water (increasing the risk of corrosion).

Damages and consequences of contaminated and prematurely ageing turbine oil

Your solution: efficient gas turbine filtration

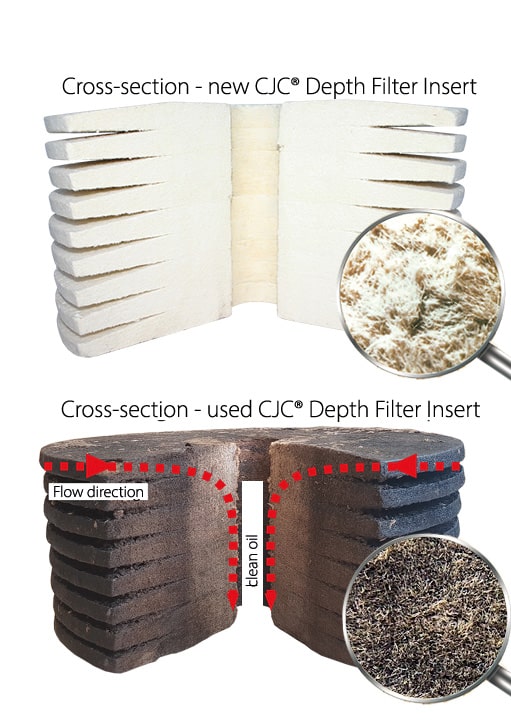

Efficient gas turbine filtration means that oxidation products, varnish, acids, particles and water are continuously removed from the turbine oil. Fact is, only with permanently clean and dry turbine oil you …

Less oil consumption

Less maintenance

Higher reliability

Higher resource protection

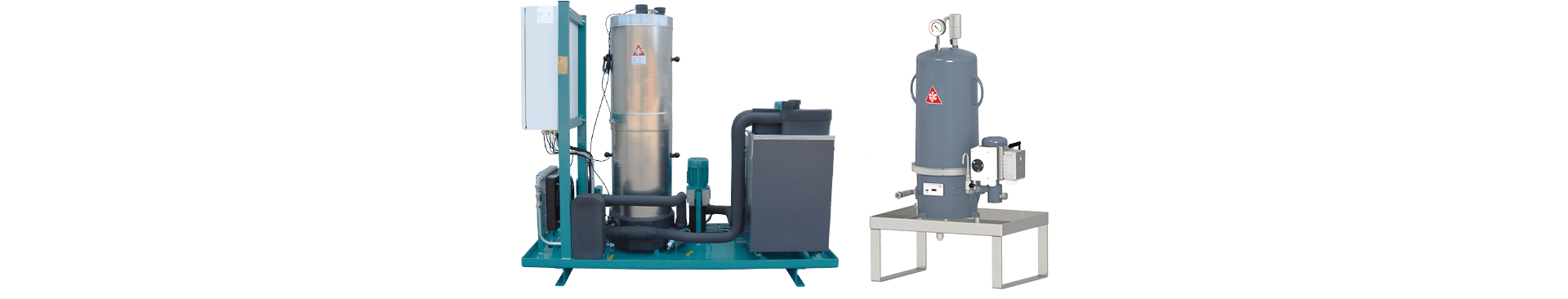

CJC® Gas Turbine Filters for efficient maintenance of turbine oil

Does your oil quickly reach high oxidation rates and acid numbers, has poor purity classes or contains water? Do you have to change or clean bearings, valves and heat exchangers frequently due to resin-like and sticky deposits? Then the CJC® Gas Turbine Filter is exactly the right solution for your gas turbine. It ensures maximum oil cleanliness in the shortest possible time — optionally documentable via our CJC® Condition Monitoring Systems. Extremely high filter capacities and separation performance make it a safe and cost-optimized solution.

Contact your regional contact now

Let’s talk about your gas turbine, the turbine oil you use and the specific challenges you face. We filter each oil. Whether you use mineral oils, synthetic fluids or fire-resistant hydraulic fluids. We work with you to maximize the service life of your lubricants and oil-lubricated components.

Receive a personal consultation and a non-binding offer for a CJC® Gas Turbine Filter for efficient oil maintenance.

Write or call us.

That say our customers

“The CJC® VRU has reduced the MPC value to low, stable and controlled levels, giving us peace of mind and the security of having clean, varnish-free oil. In addition, since the CJC® VRU Filter was put into operation, we have abserved fewer pressure filter changes and a reduction in system component failures, which has resulted in financial savings.”

“Before the installation of the CJC® Gas Turbine Filter,we were experiencing failed gas valve servo(s) just about every start. We tried other varnish removal units, but we were not getting the results we wanted. Within a short time after we installed the CJC® Gas Turbine Filter, the varnish problems we were experiencing, diminished. Our varnish levels dropped to very low levels and we have not experienced servo problems since. We are very satisfied with the results and now have again the confidence that the gas turbine will operate reliably as soon as the start button is pushed.”

„In addition to the good advice that we have always received, I positively value the effectiveness of the treatment in the short term (6 months), allowing us to prolong the lifetime of the oil, with the corresponding cost savings and reduction of the waste generated.“