How you can maximize the lifetime of your oil filling and engine components

Gas engine oil filtration: CJC® Lube Oil Filter for gas engines

How you can maximize the lifetime of your oil filling and engine components

Gas engine oil filtration: CJC® Lube Oil Filter for gas engines

Challenge

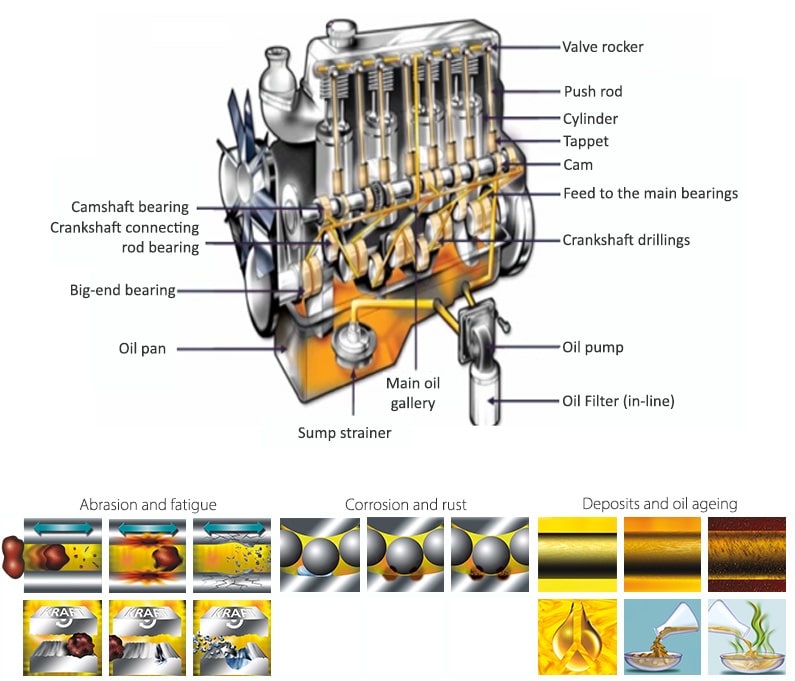

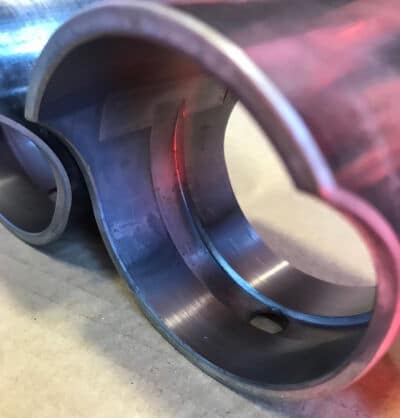

The engine oil in gas engines is permanently heavily loaded. Oxidative ageing processes, thermal load and direct contact with harmful polluted blow-by gases stress these lube oils rigorously. But also soot, metal particles, dust and humidity can ingress the oil system, partly depending on operating and engine conditions and the load. These processes accelerate each other and lead to premature base oil degradation and increased additive depletion, even when using oxidation-resistant synthetic oils. Contaminated and quickly ageing engine oil has severe consequences for the lifetime of components, engine and, therefore, the ecological and economical operation:

Damages and consequences of contaminated and rapidly ageing gas engine oil

The conventional method

Operators control the engine oil condition periodically to ensure the reliable operation of the gas engines. When the oil draws near a critical limit value, the oil sump is partly replaced (bleed-and-feed) or completely changed. But that doesn‘t reduce the impact on the engine oil. On the one hand, the newly filled-in oil contaminates within the shortest time due to deposits and dilution with dirty residual oil. On the other hand, contaminants, oxidative processes and acid stress unimpeded the engine oil‘s lubrication properties and the long-term effects of additives, which shorten the lifetime of the oil filling. That finally results only in high oil consumption. With us, however, this is more ecological and economical.

Your solution: Efficient care of the gas engine oil

Efficient engine oil care means that particles, water, oxidation residues and acids are continuously removed from the engine oil (24/7). Only with consistently clean and dry engine lube oil …

Less oil consumption

Less maintenance

Higher engine reliability

Better use of resources

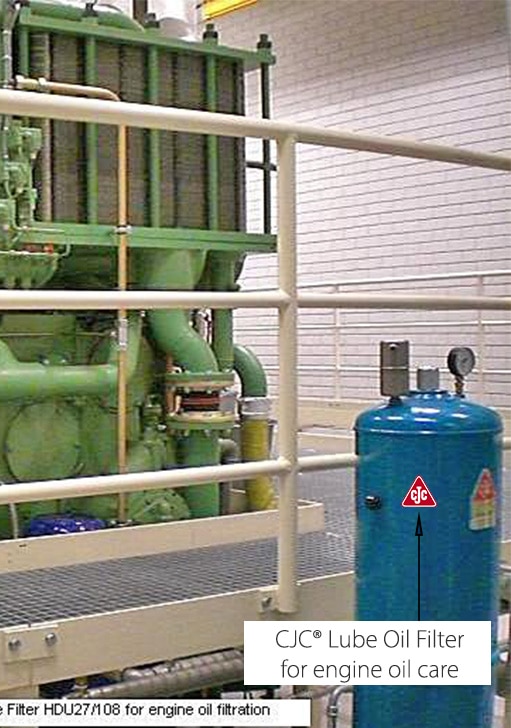

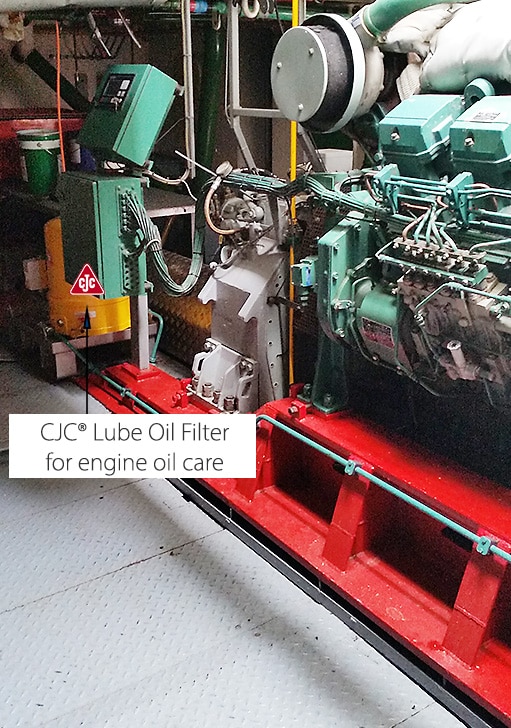

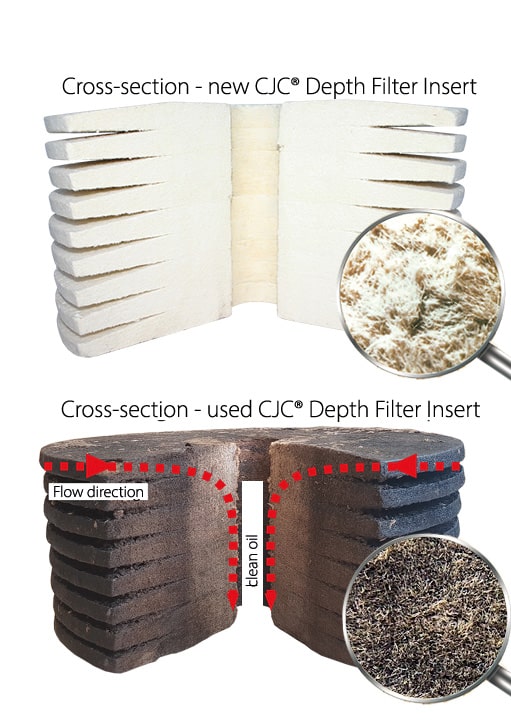

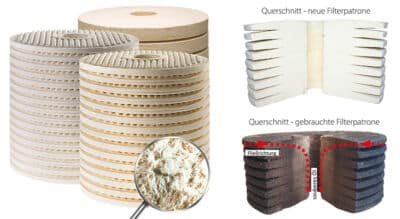

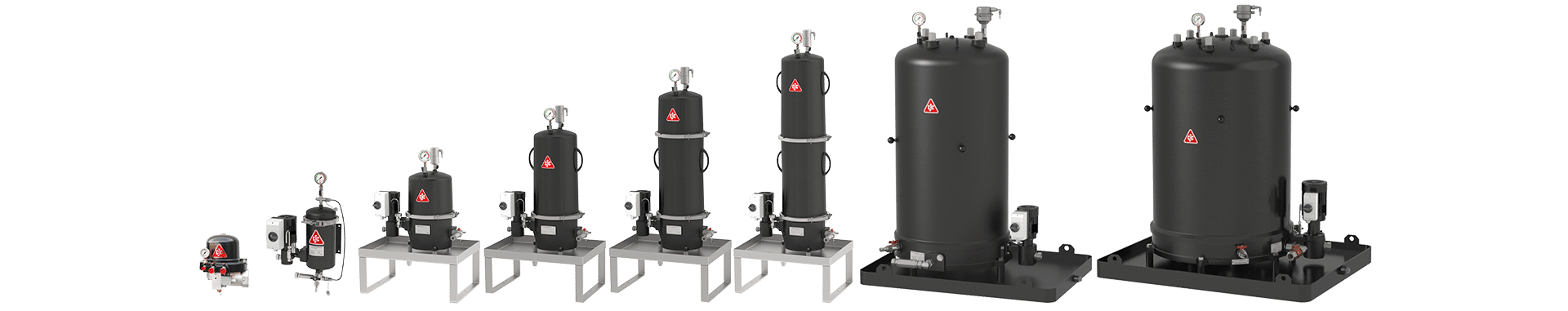

CJC® Lube Oil Filter for efficient care and filtration of gas engine oil

CJC® Lube Oil Filter for the filtration, drying and care of gas engine oil of gas engines ensure highest cleanliness classes. Offer quick, persistent and cost-optimal highest protection for your oil filling and gas engine.

Contact your regional salesperson now

Let’s talk about your gas engine, engine lube oil and specific challenges. We filter every gas engine oil, no matter whether the gas engine is operated with natural gas or special fuels such as bio, landfill or sewage gas. We maximize the lifetime of the oil filling and engine components.

Receive a personal consultation and a non-binding quotation about a CJC® Fluid Care System for efficient care and filtration of gas engine oil.

Write or call us.

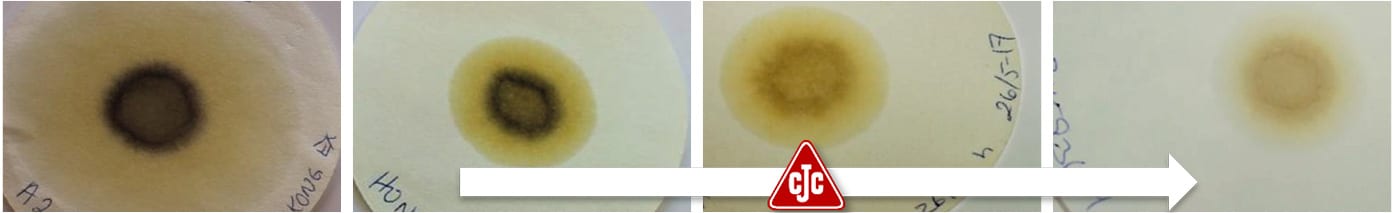

Best Practices

Application studies from the field document our customers’ savings and advantages thanks to the CJC® Lube Oil Filter for filtration and care of the gas engine oil in your engines.