How to extend the long-term stability of your fuels and ensure the reliable operation of emergency power systems

Fuel cleaning and tank care for emergency power systems: CJC® Fluid Care Systems for heating oil and diesel

How to extend the long-term stability of your fuels and ensure the reliable operation of emergency power systems

Fuel cleaning and tank care for emergency power systems: CJC® Fluid Care Systems for heating oil and diesel

Challenge

During the months or even years of storage in the storage tanks, the quality of the fuel continuously deteriorates. Impurities such as particles and water enter the tank from the outside, e. g. via leaks, leaks, condensation and tank ventilation. Even the fuel itself often does not correspond to the desired cleanliness, e. g. because there is a high risk of dirt entry during transport and transfer to your tank or the specified fuel cleanliness is unavailable on short notice in an emergency. But also oxidation and additive depletion accelerated by the impurities shorten the storage time prematurely and lead to severe consequences for the tank and emergency power system.

Damages and consequences of contaminated fuel

Common-rail systems

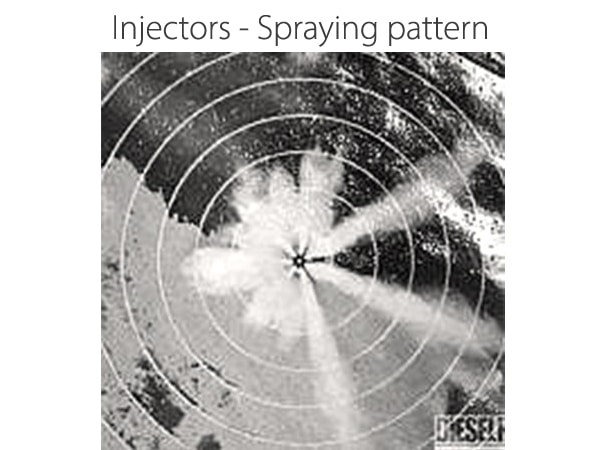

In common-rail systems, the injection timing and fuel quantity are calculated cylinder-by-cylinder and injected via fast-switching solenoid valves (injectors) to achieve improved engine performance as well as lower fuel consumption and emissions. The size of the nozzles of the injectors in common rail diesel systems is 2 – 4 microns (μm) and enables precise injection. They operate at a pressure of up to 3,000 bar. Typically, a 5-micron filter is integrated. The diesel for these systems must be up to 30 times cleaner than for standard injection systems. Due to the high pressures and tight tolerances, impurities have serious consequences.

The conventional method

To ensure the reliable start and operation of the emergency power system, operators regularly check the fuel quality. When the critical state is reached, they replace the stocks and dispose of them. The high fuel consumption is accepted, as the uninterruptible power supply must be guaranteed, and failures are more cost-intensive than the fuel. With us, however, this is more ecological and economical.

Your solution: efficient fuel cleaning

For efficient fuel cleaning, particles, water, microorganisms, oxidation products and acids must be continuously removed from the fuel (24/7). Because only with permanently clean and dry fuel you …

Lower fuel consumption

Less maintenance

Better engine efficiency

Better use of resources

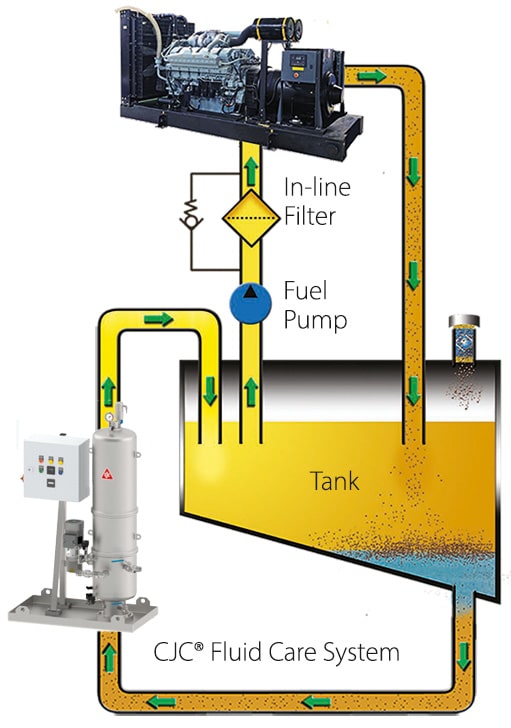

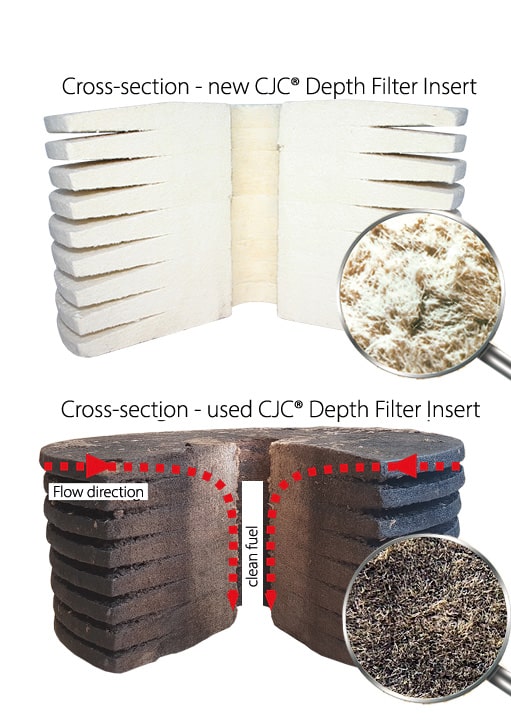

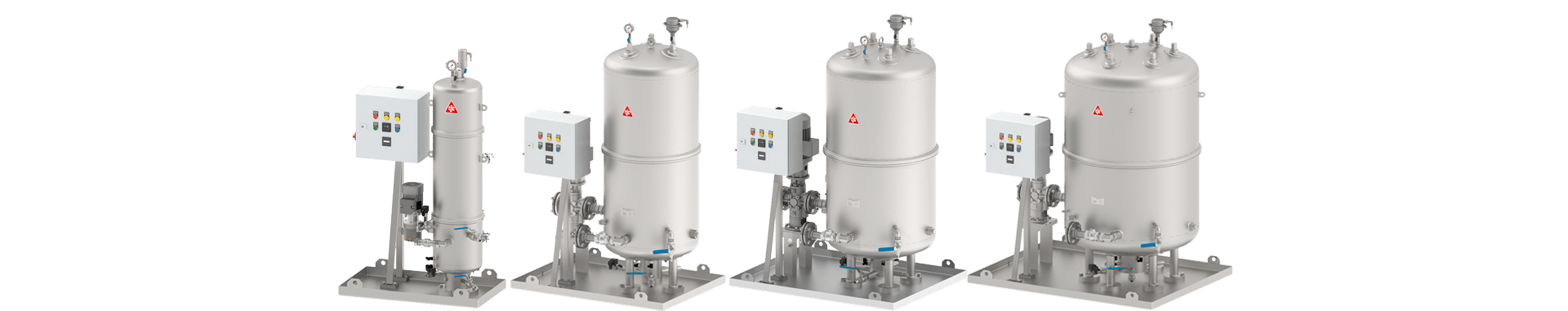

CJC® Fluid Care Systems for the efficient fuel cleaning

Efficiently remove and protect particles, water, microorganisms, oxidation residues and acids? CJC® Fluid Care Systems for fuel cleaning and tank care ensure maximum fuel cleanliness. Achieve the highest level of protection for your fuel reserves, tanks and emergency power systems quickly, long-lasting and cost-effectively.

Contact your regional salesperson now

Let’s talk about your tank care and storage challenges or your fuels. We filter every fuel, whether heating oil, fuel mixtures or diesel with biodiesel content, and maximise the long-term stability of your fuels and the wear protection of your emergency power systems.

Receive a personal consultation and a non-binding offer about a CJC® Fluid Care System for efficient fuel cleaning.

Write or call us.