Lube oil treatment on 2-stroke diesel engines | container vessels

Customer Case

System: Marine diesel engines

Vessels: Container vessels CMS “HONG KONG EXPRESS” and CMS “HAMBURG EXPRESS”, each 13.177 TEU

Main engines: 2-stroke diesel engines type MAN 11K98 ME MK 7.1 (derated to 45,100 kW at 84 rpm since 2015), low-speed 2-stroke diesel engines

Running hours: approx. 8,000 RHs/year

Lube oil, “HONG KONG EXPRESS”: Mobilgard 300, 11.9 cSt @ 100 °C

Lube oil, “HAMBURG EXPRESS”: LukOil Navigo 6 SO, 11.5 cSt @ 100 °C

Oil volume: 70 m³ (1.2 liter per kWMCR)

Container vessel “HONG KONG EXPRESS”

Tests: conventional systems vs. CJC® Lube Oil Filters

Test period: 45 weeks

Engine running hours: 5,244 RHs during the test period

Test start: approx. 24,556 RHs

Test end: approx. 29,800 RHs

Conventional lubrication oil treatment:

Two systems for each main engine.

Newly installed CJC® Marine Lube Oil Purifier:

Hapag-Lloyd AG installed on each main engine one CJC® Marine Lube Oil Purifer 3×427/81 for continuous fine filtration and dewatering (24/7/365). The four conventional systems for lube oil treatment weren’t in operation throughout the test period.

Pump flow: 3,000 litres/hour

Filter material: 100 % natural fibres (cellulose)

Filtration degree: 3 µm absolute, 1 µm nominal

Optional with oil condition monitoring

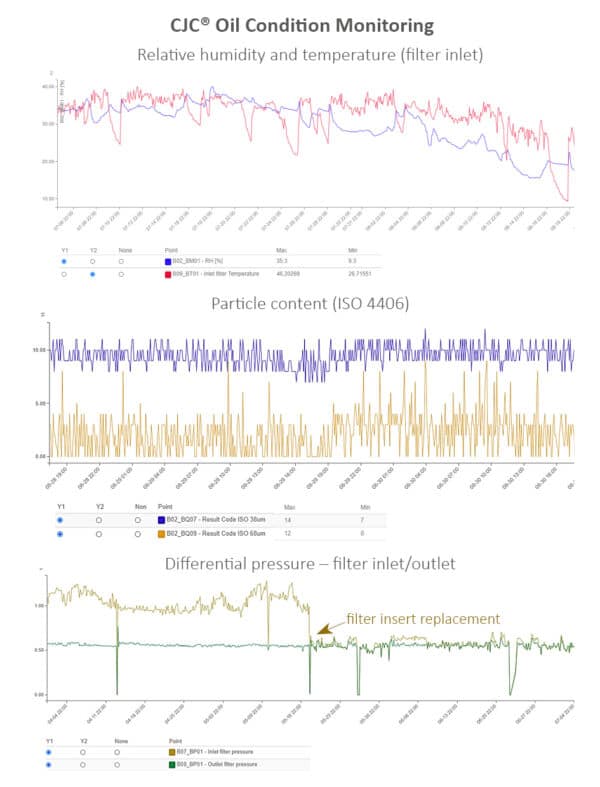

Implementing a CJC® Oil Condition Monitoring Systems on CMS Hong Kong Express enables the transfer of exact oil condition values in real-time to the command bridge. The sensor package detects differential pres-sure, temperature, relative humidity (RH %), and particle content according to ISO 4406. Deviations from the normal condition and harmful effects can be indicated at the earliest and enable counteracting – timely, cost-efficient and projectable.

Approval from MAN Energy Solutions

No Objection Letter for CJC® Lubricating Oil Filter

CJC® filter type: Marine Lube Oil Purifier 27/ or 427/ with LOX filter elements

Two-stroke engines: All types and fuels

„Tests on several ships using an off-line lubrication filtration unit with a CJC® Filter as the only cleaning unit (without centrifugal operating) have shown positive results […].“

Result of the new lube oil treatment

Several independent oil laboratories (Filtrex, AlControl/Synlab) examined the weekly oil samples. They rated the oil condition as „normal“ throughout the whole test period:

- particle and water content minimized

- stable viscosity

- stable base number (TBN)

- no impact on additives

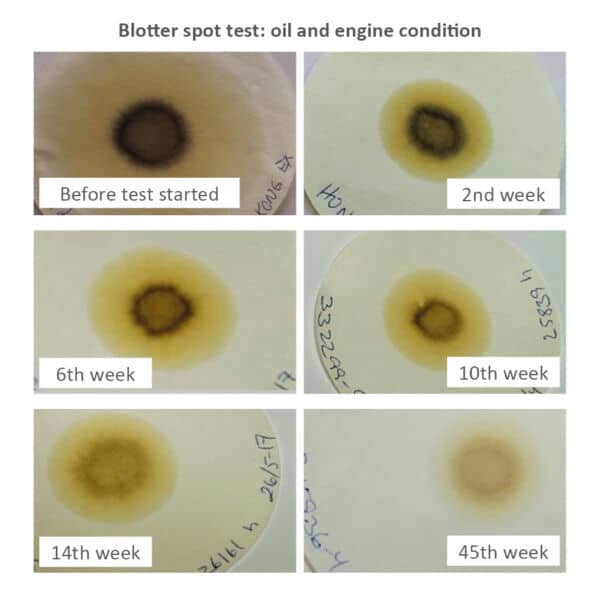

The quick blotter spot test shows that the lubricating oil was heavily contaminated with dust, metal abrasion and other particles > 1 µm before and at the beginning of the test period. Additionally, oil ageing processes (membrane colour: brown) and water ingress impact the oil (serrated border zone). Thermal load on so-called hot spots (e. g. bearings) and particles from component wear (copper, iron, aluminium) accelerate the degradation of the base oil and the additives and thus oil ageing processes. The oil was not contaminated with fuel. The oil was not contaminated with fuel. The efficient oil care with CJC® has significantly improved the oil cleanliness and dispersancy throughout the test period (see pictures on the right side). The CJC® Marine Lube Oil Purifier removes continuously and permanently particles, free, emulsified and dissolved water, oil ageing products, and acids from the engine lube oil. The conventional system has only removed particles and free water.

Savings

Approx. 98% lower lubricating oil losses in terms to lubricating oil treatment

≈ 9,846 litres of oil per year and vessel

Because of the CJC® Marine Lube Oil Purifier, Hapag-Lloyd AG saved 9,856 litres of lubricating oil a year solely due to the lower lube oil losses:

Oil losses due to filter insert replacement (CJC® Lube Oil Filter): only 144 litres/year

Approx. 97% less energy required for lubricating oil treatment

≈ 332,725 kWh per year and vessel

Using the CJC® Marine Lube Oil Purifier Hapag-Lloyd AG 332,725 kWh per year and vessel du the lower energy consumption:

Energy consumption of the CJC® Marine Lube Oil Purifier: only 10,253 kWh per year

Fewer emissions during berthing times in the port

When using conventional lubricating treatment systems during port times, the steam needed for the preheating (heating capacity 9 kW) of the lube oil – from 36 °C to 92 °C – has to be produced by the auxiliary boilers. When using CJC® Marine Lube Oil Purifier, the lube oil preheating is unnecessary. The result is that no fuel has to be burned in the auxiliary boilers during port times — i. e. drastically savings of fuel and fewer emissions.

Approx. 96% less CO2 emissions in terms to lubricating oil treatment

≈ 154,535 kg CO2 per year and vessel

The extreme discrepancy of both systems concerning energy requirements and oil losses enables Hapag-Lloyd to significantly improve the CO2 footprint of the CMS “HONG KONG EXPRESS” and CMS “HAMBURG EXPRESS” by using a CJC® Marine Lube Oil Purifier. The combustion of fuel and the thermal disposal of waste oil/sludge causes approx. 2.6 kg of CO2.

- fewer CO2 emissions due to lower energy consumption

CJC® Lube Oil Purifier: only 6,247 kg CO2/year

Operating: 6,247 kg CO2/year (2,403 Litres fuel/year x 2.6 kg CO2/litre) *

* 240 days shaft generator, HS-HFO (950 g/L), specific consumption 0.221 L/kWh and

116 days auxiliary diesel engine, MDO (880 g/L), specific consumption 0.261 L/kWh

- fewer CO2 emissions due to fewer oil losses:

CJC® Lube Oil Filter: only 374 kg CO2/year

144 Litres oil losses due to filter element replacement/year x 2.6 kg CO2/Litre

Customer Comment

„The CJC Lube Oil Purifier is proven as a reliable and efficient alternative for lube oil treatment during the excessive test periods on both vessels, which MAN Energy Solutions accompany. Due to the continuous oil care, the oil cleanliness and the lube oil’s performance are kept in the specified areas (viscosity, additives, base number, particle and water content) or were improved (e. g., dispersancy). The high savings potential regarding oil losses, energy costs and CO2emissions is convincing – even as a retrofit. An easy system with a large effect.“

Superintendent, Hapag-Lloyd AG

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations as well as a personal consultation specifically on your 2-stroke diesel engine, your lubricating oil treatment and your requirements and goals.

Write or call me.