Lube Oil Filtration for 4-Stroke Diesel Engines | Chemical Tanker

Customer Case

Marine Diesel Engines

Vessel: Chemical tanker, 19,800 GT

Engines: 4-stroke diesel engine MAN L23/30H, 800/960 kW (3 units)

Lubricating oil: Chevron TARO 30 DP30

Fuel: HFO RMG < 380 cSt, sulphur content: < 3,5%

Test: Centrifuge vs CJC® Lube Oil Filter

Test period: 8 months

Engine running time: 4,982 operating hours during the test period

Last complete oil change: at the start of the test after 3,107 hours in operation

Conventional lube oil treatment: One centrifuge for three diesel engines (DG#1, DG#2 and DG#3) and one centrifuge bypass filter (“Glacier filter”) per engine.

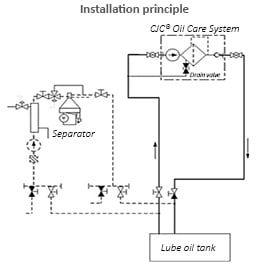

Newly installed CJC® Lube Oil Filter: During the test period, a CJC® Lube Oil Filter 27/108 was installed on each diesel engine for continuous fine filtration and dewatering (24/7/365). The automatic temperature controlled flow ensures optimum operation and the highest filtration efficiency. Pump flow: 280 L per hour (0.3 l/kW) nominal

Conclusion of the ship owner

Approx. 40-60 % lower lubricating oil consumption

Due to the lower lubricating oil losses and improved performance of the diesel engine, lubricating oil consumption has been drastically reduced. The extended oil lifetime and provided long-term lubrication is a result of the cleaner oil achieved by the enormous filter efficiency.

Fewer CO2 emissions – more than 52,000 kg CO2 per year saved

Approx. 10,400 kg of CO2 per year and ship are saved, as the amount of sludge to be disposed of (discharge from the centrifuge) has been reduced by Ø 4,000 liters. Thermal disposal of waste oil and sludge causes approx. 2.6 kg CO2 per litre. A total of five ships were retrofitted with CJC® Lube Oil Filters.

Engine reliability

In order to be able to make concrete statements regarding the improved reliability of diesel engines, the entire period between overhauls must be observed and analyzed. The maintenance and service time spent by the crew is an important indicator. The crew involved in the study rated the project as positive:

- easy to operate by the crew

- minimal maintenance requirements (insert replacement)

- Plug-and-Play-Installation

The higher oil cleanliness achieved by CJC® Lube Oil Filters definitely has a positive effect on the reliability of the diesel engine.

Savings – more than 66,000 EUR per year

The use of CJC® Lube Oil Filters results in savings of over EUR 13,000 per ship per year. A total of five ships were retrofitted with CJC®.

| Specific lube oil consumption | ||||

|---|---|---|---|---|

| Motor DG#1 | Motor DG#2 | Motor DG#3 | ||

| Operating hours | 1.145 | 8.069 | 6.680 | |

| Oil consumption [l] | 1.805 | 2.685 | 2.260 | |

| SLOCMCR* [g/kWh] | 1,58 | 0,33 | 0,34 | |

*SLOC = Specific Lube Oil Consumption MCR = Maximum Continuous Rating (maximum performance)

| Savings | |

|---|---|

| when retrofitting the CJC® Lube Oil Filter | |

Energy consumption

Centrifuge:1 x 4 kW x 23 hours x 300 days + preheaterCJC® Lube Oil Filter:3 x 0.3 kW x 24 hours x 360 days |

5,100 EUR |

Oil consumption

∅ approx. 4,000 L x 1.06 EUR/L |

4,240 EUR |

| Maintenance and spare parts | 4,000 EUR |

| Annual savings per ship | 13,340 EUR |

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your 4-stroke diesel engine, your engine lube oil and your requirements and goals.

Write or call me.