Hydraulic oil care in hydrostatic systems — Oil drying after entry of coolants

Customer case

Hydrostatic systems

Hydrostatic systems several machining centers in the production of slewing bearings and in drive technology. Turning, drilling and milling machines for the production of large parts, bearings and drive parts up to Ø 9 m.

Manufacturer: Dörries-Scharmann Technologie GmbH, Waldrich Coburg GmbH, PIETRO CARNAGHI GmbH

Oil volume: 100 to 3,000 litres, 20 to 35 °C

Hydraulic oil: Mineral oil and synthetic fluids

Cooling lubricant: water-miscible

Challenge

Leaks in seals and components (rotary distributors, tool holders, covers, etc.) in the cooling lubricant system introduce water with coolant components into the hydrostatic systems of the machines. Above a certain level, the oil becomes viscous, filters report clogging and the machine goes into trouble. Sensors for measuring the relative humidity therefore permanently monitor the water content in the oil. When the max. Limit, the color of the display of the monitoring unit changes to glow red. The customer specified max. Limit value is 80 % of the saturation limit. If the water content reaches 100% of the saturation limit, the hydraulic oil can no longer keep the water in solution, resulting in the emulsified and, depending on the water separation capacity of the oil, also free water.

As a result of the contamination, the corresponding oil system had to be emptied, rinsed and refilled with fresh oil with very high oil and oil management costs. In addition, the sometimes complicated search for causes sometimes led to longer downtimes and thus production losses. In order to reduce costs and production downtimes, Liebherr-Components Biberach was looking for a water separator that would dry the oil quickly, reliably and cost-effectively during the operation of the machine. One of the equipment manufacturers recommended one of CJC’s® oil care systems, which was subsequently tested.

Solution

in CJC® Desorber D10 with a CJC® fine filter system 27/27 was provided for testing purposes. The test was carried out in cooperation with the lubricant manufacturer, who was responsible for fluid management. The laboratory reports of the lubricant manufacturer confirm that the CJC® Desorber dries the hydraulic oil within a very short time.

Due to the convincing results and the enormous savings potential in oil and oil management costs, a CJC® Desorber D30 in combination with a CJC® Fine Filter Unit 27/54 was purchased, which can be flexibly used on all production machines. The CJC® fine filter system removes particles, oil degradation and reaction products as well as sticky residues in an independent process and thus additionally ensures the highest oil purities.

Hydraulik oil care — oil drying

The following application example was listed by the maintenance management:

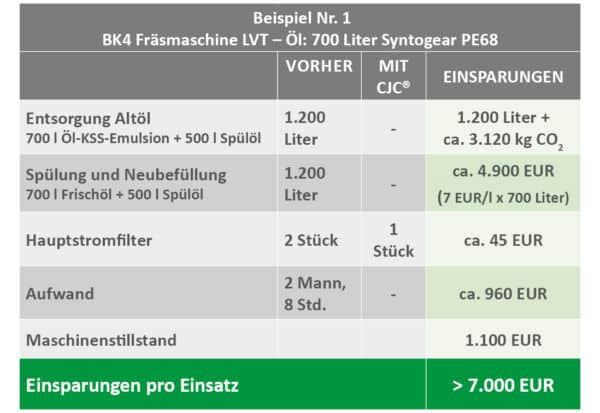

BK4 MILLING MACHINE LVT

Oil volume: 700 liters

Hydraulic oil: synthetic oil, ISO VG 68

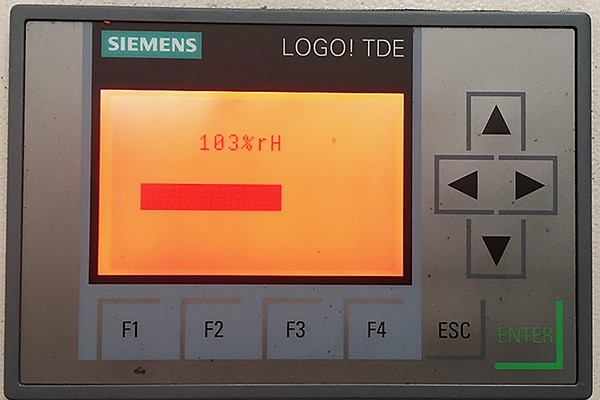

The CJC® Desorber D30 was installed on the milling machine at 3 p.m. after the humidity sensor (IFM) alarm signal at a water content of 103% rH (relative humidity).

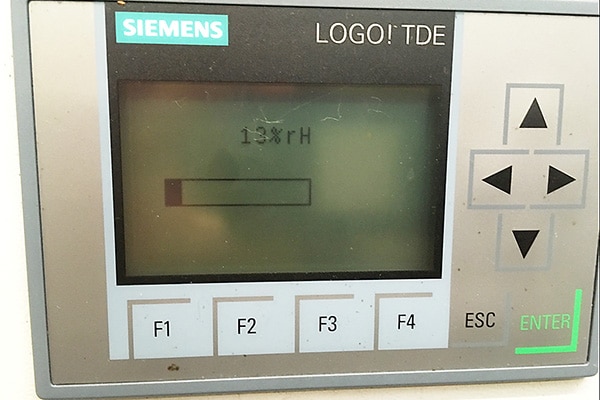

At 8:30 a.m. the next day, the relative humidity (RH) in the oil was only 13 %. Within 17.5 hours, the water content could be significantly reduced. During this time, the CJC® Desorber had separated 1.8 liters of water from the hydraulic oil.

Advantages for our customer

The use of CJC® oil care systems for efficient drying, fine filtration and care of the hydraulic oil during the operation of the machines results in the following advantages:

- Emptying, flushing and refilling of the oil systems are no longer necessary

- Higher machine availability and productivity

- Very high savings potential, very short return on investment

- Improve oil purity to protect sensitive hydro components and main flow filters and against unplanned failures

- Environmental and resource conservation

- due to fewer quantities of waste oil to be disposed of and less fresh oil requirements

- by improving the CO2 balance — the thermal disposal of waste oil produces 2.6 kg of CO2 per litre

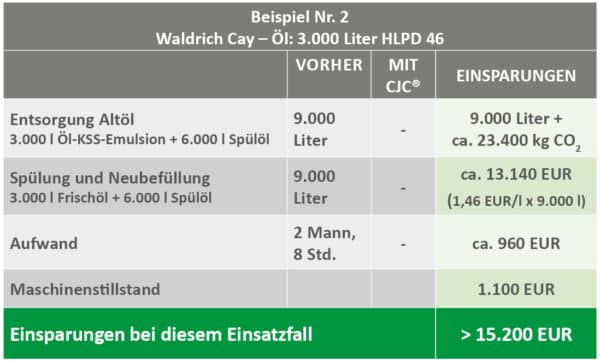

Savings

Since the commissioning of the CJC® Desorber and the CJC® fine filter system, enormous savings in oil and oil management costs have been generated. The investment had already paid off after the first deployments. The CJC® oil care systems are constantly in use and are a worthwhile investment with great impact.

Customer comment

Maintenance management:

„I am allaround satisfied with the investment. We can dry the oil very fast and with out machine downtime. Therefore, we keep the production in process, have time to search for the failure, save oil changes and the disposal of waste oil, and protect the oil quality.“

Write or call your regional contact person now

Would you like to know more about the application study? Let us start a conversation

Receive detailed information about the oil analyses and results and a personal consultation specifically on your hydrostatic system, your hydraulic oil and your requirements and goals.

Write or call us.