Hydraulic oil care | Pontoon excavator LIEBHERR P955 Litronic

Customer Case

System — Pontoon excavator

Liebherr pontoon excavator P 995 Litronic

Oil type: Biohydraulic oil (HEES) ISO VG 46

Volume: 6,400 litres

Challenge

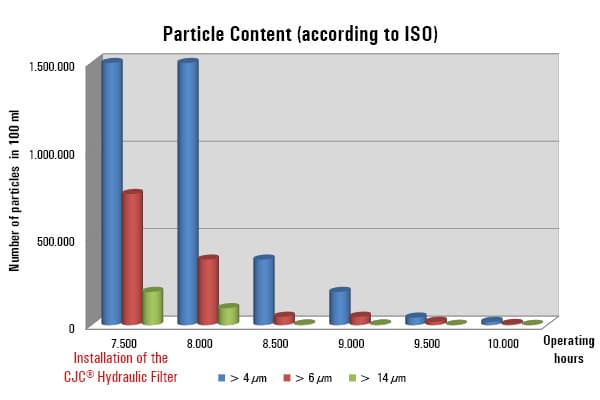

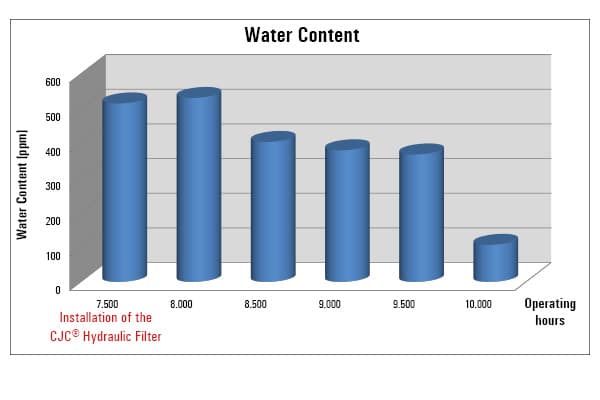

Due to the operating conditions the risk of dirt and water ingress is always high for the hydraulic system of the pontoon excavator. Despite a filter already installed on the excavator to remove water and particles, the oil was heavily contaminated. The condition of the oil deteriorated steadily, after 7,500 hours of operation, the oil reached a cleanliness class (ISO code) of 21/20/18 and a water content of 515 ppm (see table). After the failure of the pump system, the operator decided to conduct a test run with a CJC® Hydraulic Filter.

LIEBHERR P 995 Litronic pontoon excavator on stilted pontoon

Solution: CJC® Hydraulic Filter

The customer decided for a test run with a CJC® Hydraulic Filter for continuous hydrauli oil care and drying (24/7).

Dirt holding capacity: approx. 8 kg

Water holding capacity: > 3.6 Litres

Filtration degree: 3 µm absolute, retention rate < 1 µm

Filter material: 100 % natural fibres

After 7,500 hours of operation, the old filter system was dismantled and the test with the CJC® Hydraulic Filter was started. In the following months, an oil sample was taken and analyzed every 500 operating hours.

CJC® Hydraulic Filter installed on the pontoon excavator type LIEBHERR P995 Litronic

Result of hydraulic oil care

After 2 months (1,000 RHs) of continuous filtration in the offline circuit, the oil cleanliness class improved from ISO 21/20/18 to 19/16/12 and after further

2-3 months (1,500 RHs) to 15/13/10. The water content fell from 515 to 107 ppm. Because of the achieved result the oil life time will be extended and the hydraulic system will be protected against wear, a lot of costs will be saved and the environment will be spared. After the positive test the CJC® Hydraulic Filter was bought and permanently installed at the excavator.

| Running hours | ISO 4406 | Water [ppm] |

| 7.000 | 21/19/15 | 311 |

| 7,500 (installation CJC® Hydraulic Filter) | 21/20/18 | 515 |

| 8.000 | 21/19/17 | 531 |

| 8.500 | 19/16/12 | 404 |

| 9.000 | 18/16/12 | 380 |

| 9.500 | 16/15/11 | 368 |

| 10.000 | 15/13/10 | 107 |

Savings per year

Just by extending the oil change interval:

- > 6,400 litres of biohydraulic oil HEES

- approx. 12,864 EUR oil costs (2.01 EUR/L)

- approx. 30,720 kgCO2

Customer Comment

“We are very satisfied with the test progress and intend to install further CJC® fine filter systems.”

Josef Möbius Bau-Aktiengesellschaft

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your excavator, your hydraulic oil and your requirements and goals.

Write or call me.