Gear Oil Care, Thruster | Tug

Customer Case

System: Thruster

Vessel: Tugboat “BUGSIER-4”

Thruster: Wärtsilä LCT CS225-S/WN-K 1,600 kW at 1,000 rpm

Transmission oil: Shell Omala S2 GX 150

Classification: CLP DIN 51517-3

Oil volume: 1,500 liters

Motor running time: approx. 17,315 operating hours (bh) at the start of the test

Operating hours per year: approx. 1,548 hours

Challenge

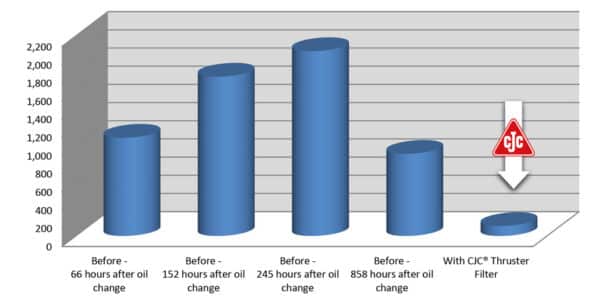

Continuous entry of water into the oil system of the thruster drive unit gearbox. Already only 66 RHS after the last, complete oil change, the water content in the gear oil was 1,080 ppm (> 0.1 %) and after a further 179 Bh 2,033 ppm (> 0.2 %). The shipping company was looking for a system that would reduce the water content efficiently and reliably within a short time, as well as being able to keep the water content at a permanently low level, even with a high water input.

Solution: CJC® Thruster Filter

A CJC® Thruster Filter consisting of Desorber D5 and oil maintenance system 15/25 was installed for test purposes. The in-house pump unit ensures continuous dewatering, fine filtration and maintenance of the gear oil (24/7/365). Water – free, emulsified and dissolved – as well as particles, oil degradation products and acids are removed from the gear oil with maximum efficiency.

Water separation capacity: permanent

Dirt holding capacity: approx. 1.1 kg

Filtration degree: 3 µm absolute, 1 µm nominal

Filter material: 100% natural fibers (cellulose)

Result of gear oil care

The CJC® Thruster filter has reduced the water content from 903 ppm (0.09%) to 109 ppm (0.01%). The zero sample and the oil sample, which were taken two months later, were analyzed by the oil manufacturer’s oil laboratory (Shell LubeAnalyst). The CJC® Thruster Filter removes free (2 phases), emulsified and dissolved water from the oil (not visible). This is important because dissolved water can be released during pressure and temperature fluctuations and is then just as harmful as free or emulsified water. Minimizing the water content – not only reducing it to the saturation limit (max. 800 ppm for CLP oils) – is essential to avoid abnormal wear, corrosion, cavitation, the impairment of lubricity, and accelerated oil degradation and thus premature oil changes.

| Before starting the test | With CJC® Thruster Filter | ||||

| Operating hours since oil change | 66 | 152 | 245 | 858 | 1.098 |

| Water content (KF), ppm | 1.080 | 1.752 | 2.033 | 903 | 109 |

| Viscosity in cSt at 40 °C | 155,1 | 153,6 | 155 | 154,5 | 154,5 |

Savings and Benefits

By installing the CJC® Thruster Filter and achieving the highest oil purity, our customer benefits from the following advantages:

- less wear

- fewer unplanned downtimes and off-hire times

- fewer losses

Customer comment

“It was only with the CJC® Thruster Filter that the transmission oil could finally be dried satisfactorily. Without CJC® we would have had to change the 1,500 liters of transmission oil soon. By avoiding the oil change, we were able to save EUR 4,890 (EUR 3.26/liter) — an important contribution not only in terms of budget, but also in terms of resource conservation. The excellent results convinced us, so we decided to purchase two identical CJC® systems for our “Bugsier 5” and “Bugsier 6″ tractors.”

Technical Superintendent “BUGSIER-4”

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your thruster, your gear oil and your requirements and goals.

Write or call me.