Transformer tray | automated drainage of water – proofed and safe

Customer Case

Transformer tray

110 kV outdoor switchgear Neuhof substation.

The Neuhof substation is a reference project for the future design and equipment of transformer stations.

Challenge

One of the customer’s objectives is to reduce the size of the pit design and thus reduce the structural envelope in the transformer tray design. The technology required for this must keep the levels in the transformer pits permanently low, i.e. control the levels and discharge collected rainwater automatically, documented and environmentally safe into the sewer system or on-site into the environment. Rainwater that may be contaminated with oil from the transformer may only be discharged if the residual oil content in the water is < 5 ppm.

Solution: SIPP™ Node

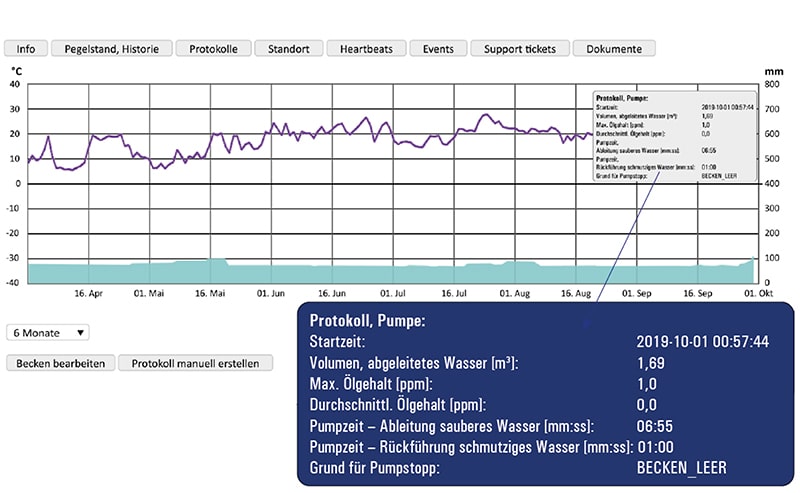

For the reference project, a SIPP™ Node 500 for fully automatic dewatering and continuous level control was installed as a pilot system on the transformer tray. The SIPP™ Node 500 is designed for an annual water volume of 50 m³, ensuring that only uncontaminated water with an oil content < 5 ppm is discharged. The SIPP™ Node 500 enables online oil content measurement with second-by-second accuracy and permanent process data acquisition during discharge. The measurement accuracy is +/- 1 ppm.

Result

Due to the fully automatic control and drainage of the transformer troughs, the water level is kept at a very low level. In most cases, the water can be discharged in strict compliance with the legal guidelines regarding residual oil content (< 5 ppm). All data on the drainage carried out and the status/activity of the SIPP™ Node 500 can be accessed online at any time via the SIPP™ Web. Server location in Germany, SSL encryption and fixed IP addresses secure data transmission.

Advantages for our customer

- Smaller pit design possible, reduced construction effort

- Sufficient oil collection volume ensured in the event of transformer damage

- Revealed enormous savings potential in terms of disposal and personnel costs:

- Minimization of the residual quantities to be disposed of in the transformer tank (water-oil mixture)

- Automation of transformer pit management, incl. Online remote monitoring

Write or call your personal contact person now

Protect your transformer stations with the innovative SIPP™ Node – the automated, environmentally friendly solution for efficient drainage of oil drip pans. Benefit from maximum retention volume, seamless documentation and considerable cost reductions.

Contact us for an individual consultation and find out how the SIPP™ Node can automate your processes. Just call or e-mail.