Hydraulic Oil Care for the ME-Hydraulic, 2-Stroke Diesel Engines | Container Vessels

Customer Case

System: Marine Diesel Engines

Hydraulic control of the injection pump and exhaust valves of the main engines (ME-Hydraulic).

Diesel engine, 2-stroke: MAN 12K98 ME-C6

Oil type: Lubricating oil, Mobilgard 300

Viscosity: 111 cSt at 40°C

Oil volume: 16,000 liters

Container vessel

Marine engine, 2-stroke, type MAN 12K98 ME-C6

Solution

Installation of a CJC® Hydraulic Filter 427/81 with CJC® Fine Filter Insert B 427/81 (3 µm absolute) for continuous fine filtration and dewatering of the hydraulic oil (24/7).

Dirt holding capacity: up to 144 kg

Water absorption capacity: approx. 14.4 l

Filtration degree: 3 µm absolute, retention rate < 1 µm

Filter material: 100% natural fibres

The CJC® Hydraulic Filter removes particles, water, oil ageing products and acidic components from the oil with high efficiency.

CJC® Hydraulic Filter for marine engines installed on the MAN engine

Savings & Benefits for our Customer

The installation of the CJC® Hydraulic Filter has ecological and economical advantages for our customer.

Due to the convincing results on the first container vessel, Hapag-Lloyd decided to install a CJC® Hydraulic Filter on further 24 vessels of different classes, extending the advantages of the CJC® Hydraulic Filter to other container vessels and optimizing a further part of the fleet.

- Prevention of malfunctions and failures in the ME hydraulic system ensures more reliable engine operation.

- Since the installation of the CJC® Hydraulic Filter, no more unplanned breakdowns occured.

- Longer service life of oil-lubricated hydraulic components reduces the need for repairs and spare parts.

- Cost reduction due to proactive maintenance, as expensive emergency repairs are minimized.

- Increased operational reliability and efficiency of the hydraulic system leads to more stable engine performance.

- Oil change of 16,000 liters of hydraulic oil avoided, thus reducing CO2 emissions.

- 76,800 kg of CO2 are saved per avoided oil change *)

*) per 1 Litre of oil approx. 4.8 kg CO2 (production/disposal)

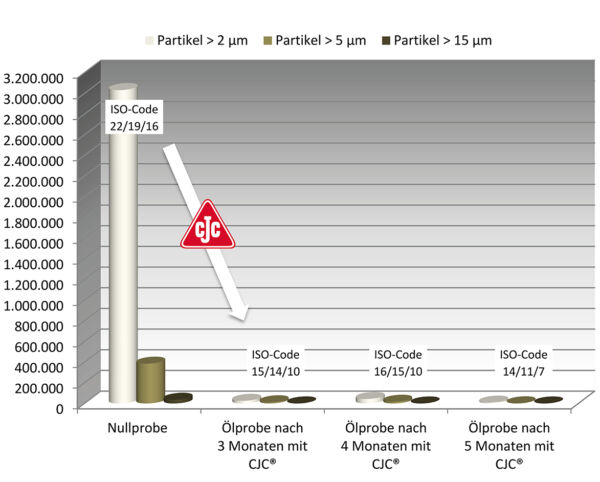

Particle content in 100 ml oil (ISO 4406)

| Results of the oil analysis | ||||

|---|---|---|---|---|

| Zero sample | After 2.5 months | After 4 months | After < 5 months | |

| Particles > 2 µm | 3.031.840 | 25.398 | 43.610 | 8.465 |

| Particles > 5 µm | 384.800 | 11.544 | 16.936 | 1.539 |

| Particles > 15 µm | 35.650 | 633 | 725 | 66 |

| Oil cleanliness classes ISO 4406 | 22/19/16 | 15/14/10 | 16/15/10 | 14/11/7 |

| Water, ppm | 1.300 | 1.100 | 1.065 | 851 |

Customer Comment

“Only by installing the CJC fine filter system can the requirements for the ME hydraulic system be met.”

Superintendent

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations as well as a personal consultation specifically for your ME hydraulic system, your hydraulic oil and your requirements and goals.

Write or call me.