Hydraulic Oil Care in the Offline Circuit, Winch | Tug Bot

Customer Case

Hydraulic system, winch

Vessel: Tug boat “BEAUFORT”, 2010 built by Damen shipyard in the Netherlands

Hydraulic oil: Shell Tellus 46

Oil volume: 1.200 Litres

Challenge

High temperatures extremely load the hydraulic oil of the winch and accelerate oil ageing processes with immense consequences for the entire hydraulic system. To value the oil more precisely, an oil sample was taken and analysed by an independent laboratory. Result of the analysis: high Varnish and particle content, the oil was so contaminated that exact particle counting was not possible, black membrane filter. The hydraulic system was extremely dirty.

At that point, the Dublin Port Company had already installed a CJC® Hydraulic Filter 27/108 in the offline circuit on their RoRo Ferry ramp hydraulic system. Because of the excellent results on the ferry, the ship owner decided to test such a CJC® filter for the tug boat’s winch hydraulic system.

Tug boat “BEAUFORT”

Solution

A CJC® Hydraulic filter 27/27 was installed. The installation in the offline circuit ensures continuous fine and depth filtration, drying and care of the oil.

Filter material: 100% natural fibres

Filtration degree: 3 µm absolute, retention rate < 1 µm

Dirt holding capacity: up to 10 kg

Water holding capacity: approx. 0.9 Litres

Result with CJC® Hydraulic Filter

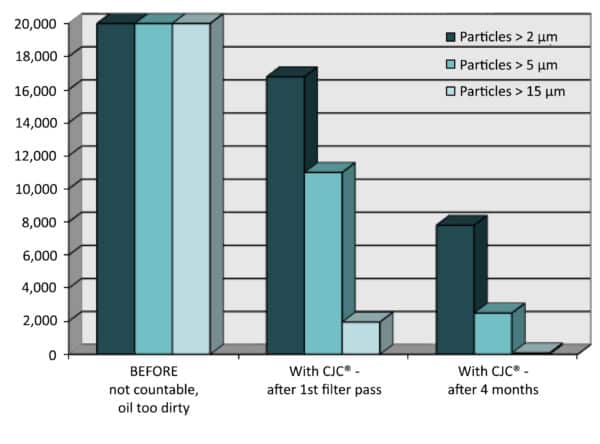

The sample that confirmed the poor oil condition was taken in December – the cleanliness class according to ISO 4407 was approximately 22/20/14. The oil was so contaminated and dark that an exact particle number was not countable and impeded the ISO Code’s classification. The CJC® Hydraulik Filter was installed shortly after the report of the laboratory. Already after the first filter pass, a second oil sample was taken – the oil cleanliness level improved to 15/14/11 (acc. to ISO 4407). Four months after the installation of the CJC® Hydraulic Filter, a further analyses was taken and documented the ISO Code 13/12/7 – perfect condition for optimum system reliability. No problems were seen on the winch system anymore. According to Noria Corporation, the estimated lifetime for hydraulic components is 10-times longer when the oil cleanliness (ISO Codes) can be improved in such impressive magnitude.

Oil samples

BEFORE

without care

With CJC®

after 1st filter pass

With CJC®

after 4 months

Einsparungen & Vorteile für unseren Kunden

Durch die Installation des CJC® Hydraulikfilters hat unser Kunde folgende Vorteile erzielt:

- Risiko Charter-Buchungen zu verlieren gesenkt (Off-hire-Zeiten)

- zuverlässig funktionierende Winde durch dauerhaft sauberes Hydrauliksystem — Pumpen, Ventile und Kolben optimal geschützt

- 10-mal längere Lebensdauer für Hydraulikkomponenten möglich

- Ölwechsel vermieden und 1.200 Liter Hydrauliköl gerettet

- CO2-Emissionen reduziert — 5.760 kg CO2 werden eingespart pro vermiedenen Ölwechsel *)

*) ca. 4,8 kg CO2 pro 1 Liter Öl (Herstellung / Entsorgung)

| Zero sample BEFORE |

With CJC® Hydraulic filter after 1st filter pass |

With CJC® Hydraulic filter after 4 months |

|

| Particles > 2 µm |

not exactly measurable | 16.780 | 7.804 |

| Particles > 5 µm |

not exactly measurable | 10.995 | 2.496 |

| Particles > 15 µm |

not exactly measurable | 1.950 | 77 |

| ISO Code 4407 *) | 22/20/14 | 15/14/11 | 13/12/7 |

*) Information on the determination of cleanliness classes and oil analyses available on request.

Customer Comment

„I would highly recommend talking to CJC! Especially if you are experiencing any oil condition problems, this system works!“

Technical Supervisor, Dublin Port Company

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your winch, your hydraulic oil and your requirements and goals.

Write or call me.