Hydraulic oil maintenance | Sand-lime brick presses

Customer Case

Sand-lime brick press type 1200 J

Sand-lime brick press type 1200 J (Dorstener Maschinenfabrik)

Oil volume: 3,800 liters

Oil type: Hydraulic oil SRS Wiolan HLP-D 46

Challenge

During the processing of sand-lime bricks, large quantities of extremely fine particles are produced, which enter the oil circuit from the environment and pollute it. With a cleanliness class of 24/22/19 (according to ISO 4406), the oil did not correspond to the purity classes from 20/18/15 (main valve) to 17/15/12 (pilot valve) required by the manufacturer (manufacturer: Bosch Rexroth) for the highly sensitive valve technology of the hydraulic system. Massive jamming, various failures in the proportional valves, and frequent changes in the pressure and cooler filter led to increased maintenance costs and numerous production losses. Despite changing the oil, filtering the entire oil volume and installing a new return filter with a filter fineness of 3 µm, the oil became contaminated again within 6 months. The problems with the proportional valves and the short filter life increased again.

Solution: CJC® Off-line Filter

CJC® Off-line Filter 27/54 with integrated depth filter cartridge for continuous off-line oil maintenance (24/7).

Dirt holding capacity: up to 24 kg

Water absorption capacity: > 1.8 l

Filtration degree:3 μm absolute, 1 μm nominal

Filter type / material: Depth filter made of 100% natural fibers

Result

Despite the immense and permanent dirt input – among other things, due to a severe leak on a hydraulic cylinder – the CJC® Offline Filter reduced the particle content quickly. The content of particles > 4 μm decreased by a total of 99.31%.

Result of significant improvement in oil purity:

- Pressure and return filters (cooler):

The filter life of both main flow filters has been extended from 2 to 4 to 6 weeks.

Savings per half-year: approx. 2,250 EUR - Proportional valves:

The valve technology works reliably, with no clamping valves. Unplanned downtimes and production losses are avoided. - Oil purity:

The oil does not need to be changed again.

Savings: approx. 3,800 EUR (1 EUR/litre)

The service life of oil and components is expected to be extended by 3 to 7 times (Source: Noria Corporation)

Due to the convincing results and the high savings potential, the remaining two sand-lime brick presses will also be equipped with CJC® Offline Filters. The payback period of the CJC® Offline Filter is less than one year.

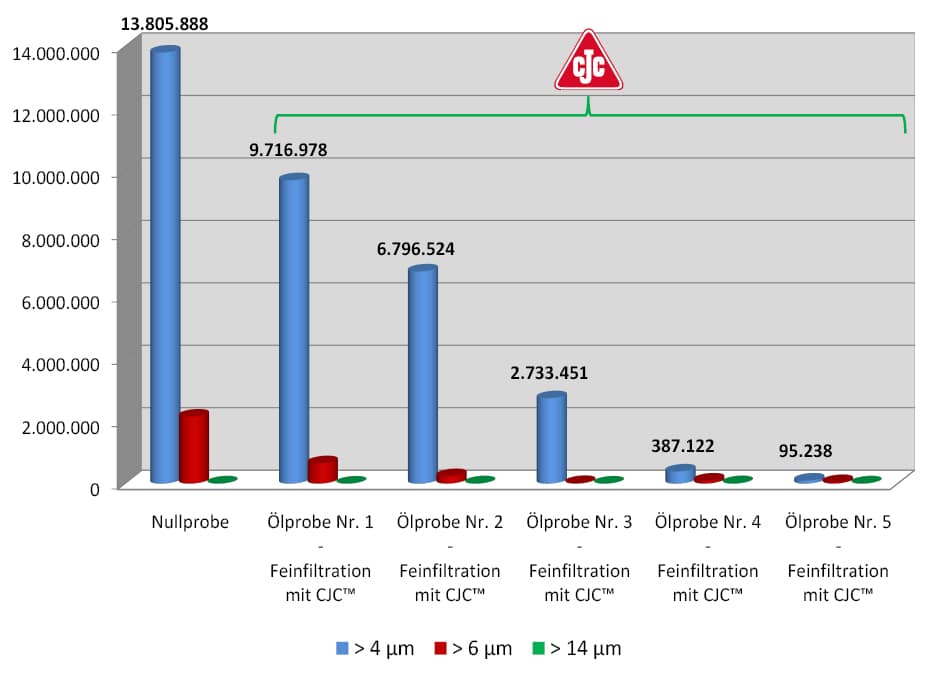

Oil analysis

| Fine filtration with CJC® Offline Filter |

||||||

| Zero sample | Oil Sample No. 1 | Oil Sample No. 2 | Oil Sample No. 3 | Oil Sample No. 4 | Oil Sample No. 5 | |

| Particles > 4 µm | 13.8 million | 9.7 million | 6.7 million | 2.7 million | 387.122 | 95.238 |

| ISO code 4406 | 24/22/13 | 24/20/12 | 23/18/14 | 22/15/11 | 19/17/14 | 17/16/3 |

Information on the oil analyses is available on request.

NOW WRITE OR CALL YOUR REGIONAL CONTACTPERSON

Would you like to know more about the application study? Let us start a conversation

Get detailed information about the oil analysis and results and a personal consultation specifically regarding your gas engine, engine oil and requirements and aims.

Write or call us.