Gear Oil Maintenance, Thruster | Harbour Tug

Customer Case

System — Thruster

Vessel: Harbour tug “VB PORNIC”

Thruster: AQUAMASTER US 1401 AZIMUTH Starboard Thruster

Gear oil: EPONA Z 100 (marine mineral gear oil)

Viscosity: 100.7 cSt @ 40 °C

Oil volume: 850 litres

Challenge

Entry of seawater into the gear oil of the thruster of the tug (starboard side). The mineral oil-based gear oil was contaminated with water (0.39%) and sodium (22 ppm). As the next inspection in the dry dock was not scheduled for another 6 months, our customer was urgently looking for a solution to be able to operate the tug reliably until then.

Harbour tug “VB PORNIC”

Solution: CJC® Thruster Filter

A CJC® Thruster filter consisting of Desorber D5 and oil care system 15/25 was installed. The installation of the CJC® Thruster Filter in the offline circuit ensures continuous dewatering, fine filtration and maintenance of the gear oil (24/7/365). Water — free, emulsified and dissolved — as well as wear particles and oil degradation products (varnish, acids) are removed from the gear oil very efficiently.

Water separation capacity: > 150 ml/h

Dirt holding capacity: approx. 1.1 kg

Filtration degree:3 μm absolute, 1 μm nominal

Filter material: 100% natural fibres (cellulose)

BEFORE — without gear oil maintenance

Result of gear oil maintenance

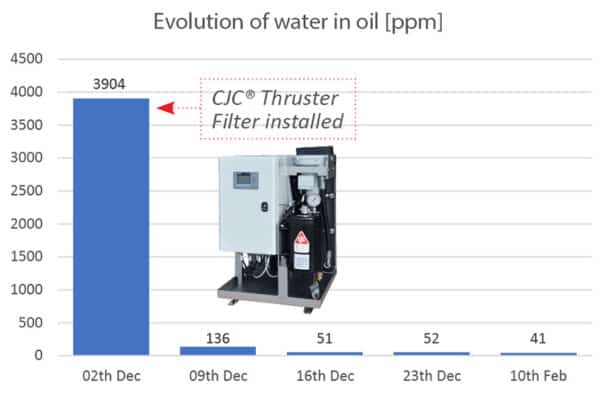

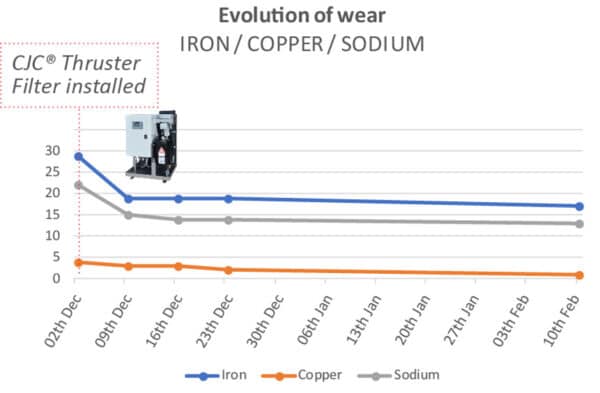

Weekly oil samples were taken to follow the oil condition and trend. After a week, the CJC® Thruster Filter had removed the water from the gear oil — the water content in the oil dropped from 3,904 to 163 ppm. According to Noria Corporation, this corresponds to a lifetime extension factor of 5-6 for the oil and equipment. The recommended water content of the gear oil amount < 300 ppm. Moreover, the CJC® Thruster Filter removed solid particles from the gear oil — wear debris such as iron (FE) and copper (CU) were lowered from 29 and 4 ppm down to 17 and 1 ppm; the sodium/salt content (NA) decreased from 22 to 13 ppm. The content of these impurities should not exceed 25 ppm as recommended.

Oil samples

BEFORE — without gear oil maintenance

Water: 0.39%

Sodium: 22 ppm

After 3 weeks with CJC® Thruster Filter

Water: 0.05%

Sodium: 14 ppm

Savings and Benefits

The installation of the CJC® Thruster Filter results in the following advantages for our customer:

- Cost-intensive emergency inspection in dry dock avoided

- Oil filling service life and thruster components extended by 5 to 6 times

- Oil change avoided and 850 litres of gear oil saved

- Permanently clean and dry gear oil ensured – free of water, wear particles, and salt crystals/sodium

By avoiding the oil change and drastically extending the service life of the oil filling in the future, the CO2 footprint of the tug improves – a valuable contribution to BOLUDA’s strategic goal of becoming a CO2 neutral company.

Customer Comment

“The CJC® Thruster Filter allows us to keep the tug in operation until the scheduled dry dock inspection in 6 months. The results of the oil analyses are clear and clearly demonstrate the effectiveness of the CJC® Thruster Filter.”

Regional Technical Manager, Mr. Olivier GLOAGUEN

Contact your maritime technical salesperson now

You would like to know more about the customer case? Let us start a conversation

Receive detailed information on the oil analyses, savings and calculations and a personal consultation specifically on your thruster, your gear oil and your requirements and goals.

Write or call me.