How you can achieve a permanently high dielectric strength, secure the filling volume in transformer pits and increase operational safety

CJC® Filter for transformers: longer service life for transformers and more automation

How you can achieve a permanently high dielectric strength, secure the filling volume in transformer pits and increase operational safety

CJC® Filter for transformers: longer service life for transformers and more automation

Challenge

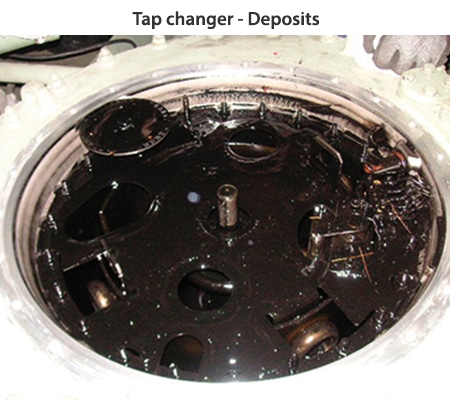

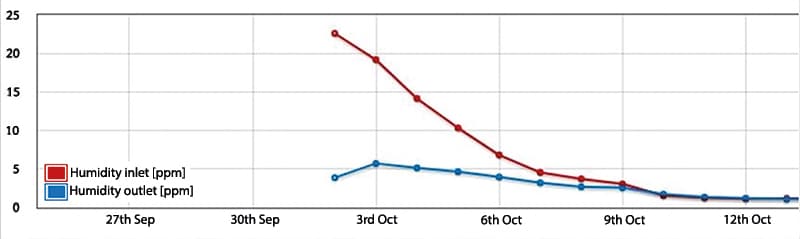

The cellulose insulation of transformers is prone to molecular decay as a result of chemical ageing processes. This creates water in the cellulose insulation, which is released into the transformer oil where it can adsorb to suspended particles in the oil. Water molecules act as conductivity bridges, which reduces the dielectric strength and thus the operational reliability of the transformer. The risk of short circuits and partial discharges increases. The chemical ageing of the insulating oil also leads to deposits and an increase in acidity. Water, acids and oxygen are the primary accelerators for further ageing of the transformer insulation (oil and cellulose). Therefore, the aim of sustainable transformer maintenance should be the permanent and gentle drying of the cellulose insulation, as well as the continuous removal of water, suspended solids, ageing products and acids from the insulating oil. Oil changes and temporary oil drying only lead to a short-term improvement.

But also ensuring the functionality of transformer pits is one of the challenges. Water can accumulate in the oil catch basins due to rain and snow, which means that there is insufficient capacity in the event of an oil spill. The water must therefore be regularly removed from the basins and, if contaminated with oil, disposed of in accordance with environmental guidelines – typically creating high personnel costs and high disposal costs.

Consequences of water in the transformer insulation and the transformer pits

Disadvantages of conventional methods

Discontinuous transformer drying and oil change:

Changing the oil only removes a fraction of the water, because most of the water inside a transformer is in the cellulose insulation (windings). In a transformer with, for example, 20 tons of oil weight and 40 ppm oil moisture, only 0.8 liters of water are retained in the insulating oil, but around 100 liters in the cellulose insulation. It is therefore crucial to dry the cellulose insulation and not just the oil.

An oil change due to a high level of contamination and/or acidity can also normally be avoided, as the oil can be treated with adequate fine filtration and can continuously used for many months and even years.

Vacuum drying:

Temporary vacuum drying has significant disadvantages in terms of time and costs. The drying process cannot usually be carried out on site. The costs and effort involved in transporting the transformer are enormous. The longer the drying process takes, the greater the increase in costs due to the resulting loss of use. Shorter drying processes, on the other hand, reduce efficiency: only the oil is dried, but not the cellulose insulation, as the water only diffuses slowly from the insulation into the oil.

In addition, the vacuum process puts a strain on the cellulose insulation, which is already affected by chemical ageing, as compression is reduced, which can damage the winding during further operation. The gas-in-oil analysis, which is crucial for assessing the functionality and safety of a running transformer, is also impaired by the vacuum process, as gases are removed, making it difficult to accurately assess the safety status.

Your solution: an efficient filter for transformers

Efficient filtration in transformer stations means, on the one hand, installing a system that gently and thoroughly dries the cellulose insulation of the transformer in continuous operation and simultaneously removes impurities, suspended solids and deposits from the oil, and on the other hand, installing a system that ensures the functionality of the oil catch basins — at all times. Fact is, only with efficient and proofed systems you …

Less oil consumption

Less maintenance

Higher reliability

Better protection of resources

CJC® Filter for transformers: more efficiency and automation

Does the dielectric strength and acid number of the insulating oil increase briefly after the transformer has dried? Do you frequently replace the oil and do deposits prolong the cleaning procedure during the revision? The cost of emptying the collection basins is disproportionately high? Then the CJC® Transformer Oil Filter and the SIPP™ Node are exactly the right solution for your transformer stations.

The transformer oil filter ensures continuous drying of the cellulose insulation and maintenance of the insulating oil, and the SIPP™ Node ensures the automated drainage of water from the catch basins. Everything can be documented using the integrated sensor technology. Both solutions impress with their innovative approaches and high separation efficiency and precision.

Contact your regional contact now

Let’s talk: about your transformer pit, your transformers and catch basins and the specific challenges. We ensure optimum drying and maintenance of transformer oil and enable the automated, environmentally safe draining of water from transformer pits. Together with you we maximize the service life of your insulating oils and transformers and increase the automation level of your processes.

Receive a personal consultation and a non-binding offer for a CJC® Transformer Oil Filter and a SIPP™ Node.

Write or call us.

That say our customers

” […] SIPP has the necessary technical approvals, while the company has the capacity and expertise to adapt and develop the system to meet different needs. The SIPP Node also gives us the necessary freedom to use our employees for complex tasks that cannot be automated. Using the SIPP Node also gives us greater and consistent accuracy in sampling the collected water, which helps us achieve our high environmental protection requirements. The basic prerequisite remains that the approval authorities agree to its use. This in turn depends on the legal framework and applicable limits.”

“The biggest advantage is that we now have an automated monitoring system, which in practice means that we no longer have to think much about measuring and emptying our transformer pits. Instead of regularly sending out an electrician to monitor the transformer pits, we now have full control at each time. Occasionally, the filters and measuring cells have to be changed, but otherwise most of it is automatic.”