How you can reduce malfunctions and failures with the right filtration strategy

Filtration in hydropower plants – the best solution: CJC® Water Turbine Filter

How you can reduce malfunctions and failures with the right filtration strategy

Filtration in hydropower plants – the best solution: CJC® Water Turbine Filter

Challenge

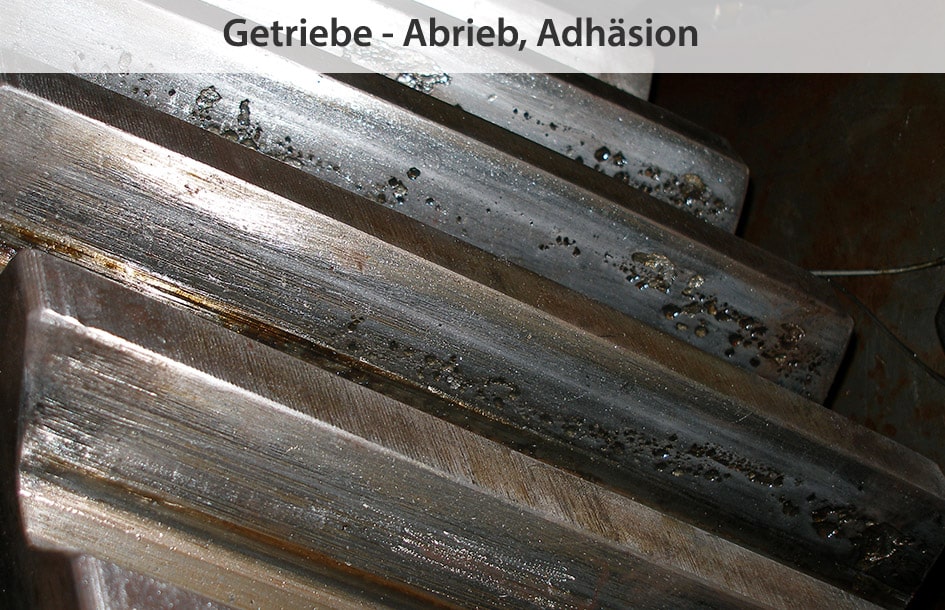

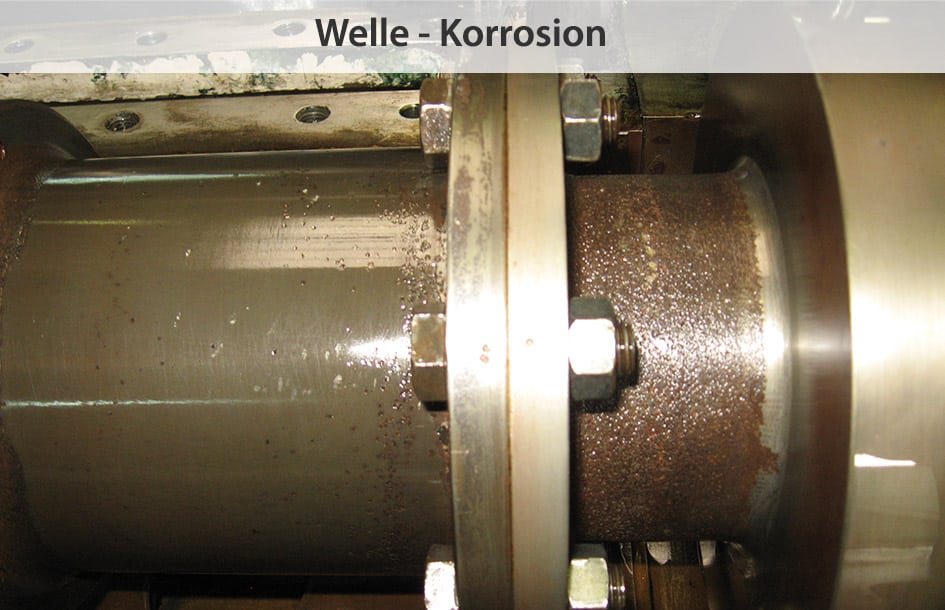

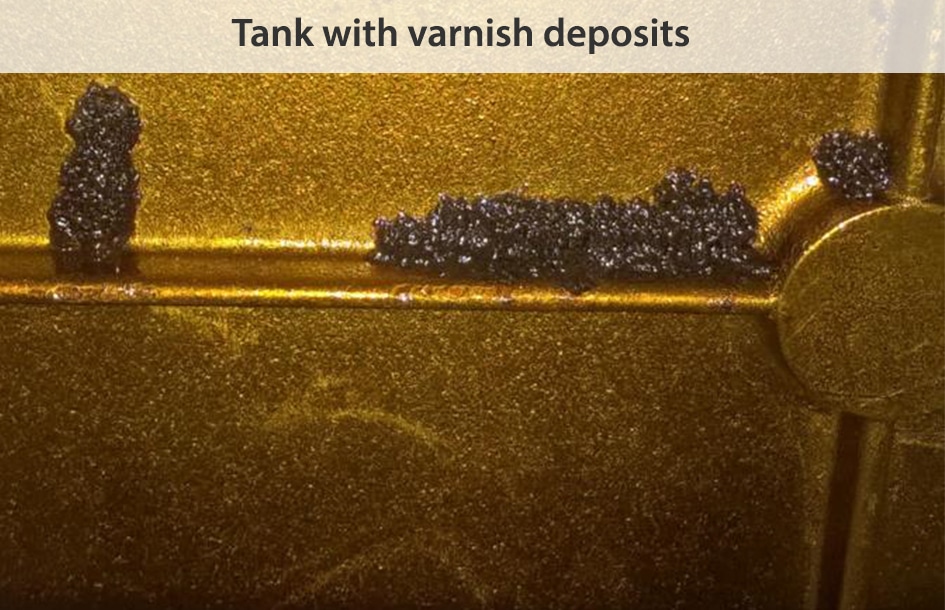

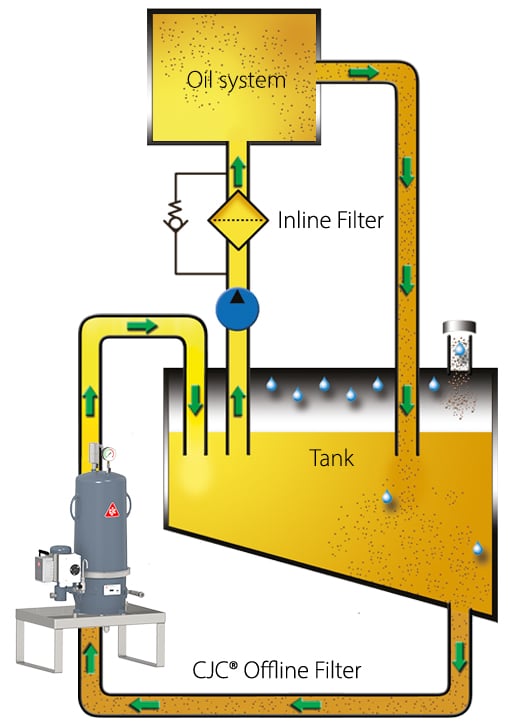

Dry and clean lubrication and control systems in water turbines are crucial to prevent expensive repairs and downtime. The main problems are water ingress and wear particles from the gearbox, which lead to malfunctions in the lubrication and control system and accelerate oil degradation processes. With new water turbines, there are more particles in the oil right from the running-in period, which means that there is an increased risk of wear from the very first second. If power generation fails due to unplanned downtimes, this can result in high contractual penalties. A water turbine filter that efficiently removes water, particles and oil degradation products from the turbine oil is therefore your key to higher turbine availability and lower costs.

Damages and consequences of contaminated and prematurely ageing turbine oil

Your solution: efficient water turbine filters

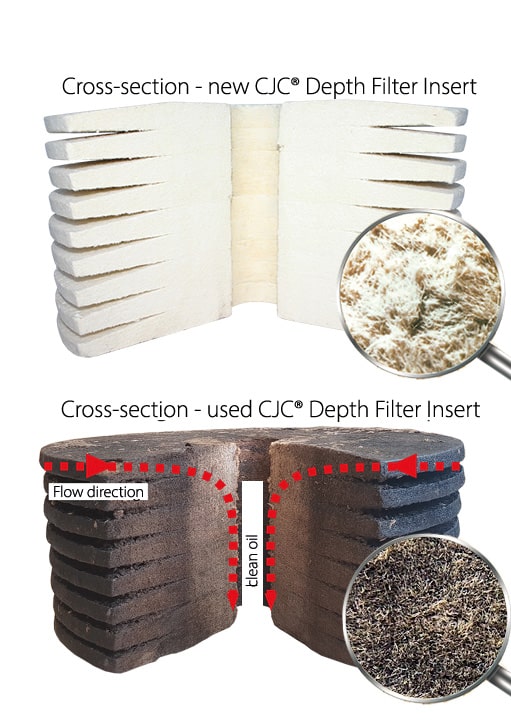

Efficient filtration in hydropower plants means that particles, water and oxidation products are continuously removed from the turbine oil. Fact is, only with permanently clean and dry turbine oil you …

Less oil consumption

Less maintenance

Higher reliability

Higher resource protection

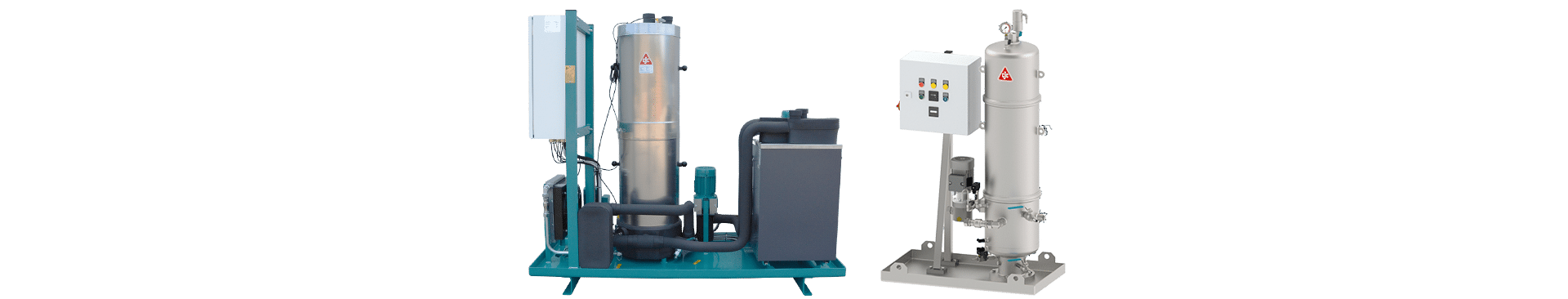

CJC® water turbine filters for efficient filtration in hydropower plants

Oil analyses show a high water content and degree of contamination in your turbine oil? Do you have to replace gearboxes, bearings, valves and hydraulic components frequently due to wear? Then the CJC® water turbine filter is exactly the right solution for your hydropower plant. It ensures maximum oil cleanliness in the shortest possible time – optionally documentable via one of our CJC® Condition Monitoring Systems. Extremely high filter capacities and separation performance make it an efficient and cost-optimized solution.

Contact your regional contact now

Let’s talk about your water turbines, your lubrication and control oil systems, the turbine oil you use and the specific challenges you face. We filter each oil. Whether you use mineral oils, synthetic fluids or fire-resistant hydraulic fluids. We work with you to maximize the service life of your lubricants and oil-lubricated components.

Receive a personal consultation and a non-binding offer for a CJC® water turbine filter for efficient oil maintenance.

Write or call us.

That say our customers

„The laboratory reports have confirmed our first-hand impression after the visual inspection: From day one, the effect was evident (see photos of the oil samples). Our control valves work precisely and reliable again, and the oil quality meet the requirements. In a month, we treated the hydraulic oil in 2 tanks with the CJC® Filter and reached the same results. Components such as flow-blocks and pumps are now preserved more effectively against wear.“

“The CJC® Filter Separator is not only very easy to operate and extremely low-maintenance, it also allows us to completely dispense with the use of the centrifuge. I am more than satisfied with the results.”

„I am very pleased with the results, we have obtained with the new CJC® Oil Care Systems. The approach of analysing the results for G3 before purchasing for the other eight units, made the decision easy for our controller.“