How you minimize repair costs and off-hire times

Filtration and maintenance of gear oil: CJC® Thruster Filters

How you minimize repair costs and off-hire times

Filtration and maintenance of gear oil: CJC® Thruster Filters

The challenge: water in gear oil

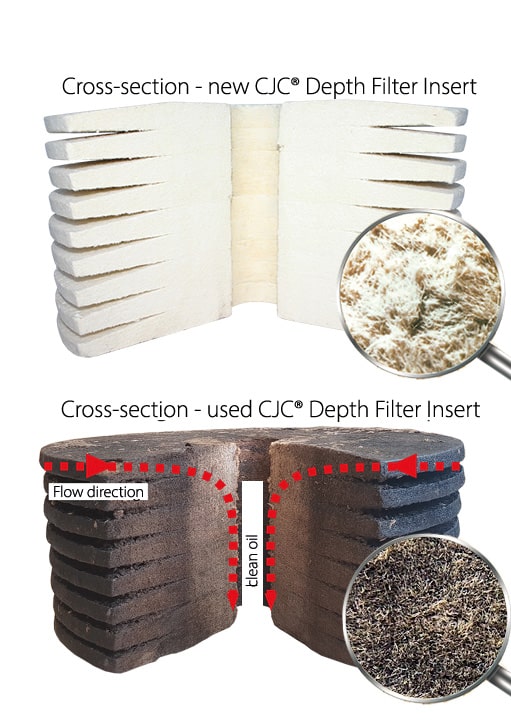

Water in the gear oil of thrusters causes high costs for vessel operators as a result of unplanned lay days due to oil changes and repairs to the thruster. Water in the gear oil is the leading cause of malfunctions of a thruster due to damage to the propeller control, shaft, bearing and gearbox. Unfortunately, despite technical developments, water ingress is not entirely avoidable: water ingress through damaged, worn shaft seals or by overcoming the static pressure The shaft seals usually wear out from particles in the oil. In particular, particles < 1 μm have an abrasive effect due to the low dynamic tolerance. Additionally, when biodegradable lubricants are used, they decompose on contact with water or form stable oil-water emulsions. Premature oil changes are costly in these cases, because these special oils are 3, 5 and even up to 8 times more expensive than mineral oils. Watery, contaminated and rapidly ageing oil has severe consequences because if the thruster drive does not work, you have to accept docking and costly repairs while losing orders:

Damage and consequences of contaminated gear oil in thrusters

The conventional method

To ensure the reliable operation of the thruster, the inspectors regularly check the gear oil. When the oil draws near a critical limit value, the oil sump is partly replaced (bleed-and-feed) or completely changed. However, this does not reduce the load on the gear oil. On the one hand, the newly filled-in oil contaminates within the shortest time due to deposits and dilution with dirty residual oil. On the other hand, impurities, oxidative processes and acids unhindered strain the gear oil’s lubricating properties and the additives’ long-term effect, which shortens the service life of the oil filling. That finally results only in high oil consumption. With us, however, this is more ecological and economical.

Your solution: Efficient care of the gear oil

Efficient gear oil care means continuously removing water, particles, oxidation residues and acids from the gear oil (24/7). Because only with permanently clean and dry lubricant …

Less oil consumption

Less maintenance

Higher reliability

Higher resource protection

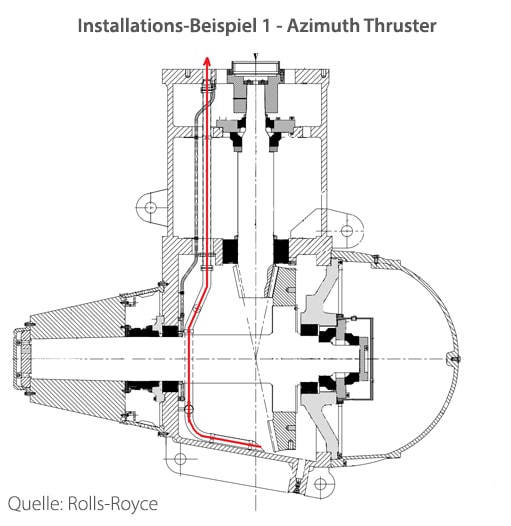

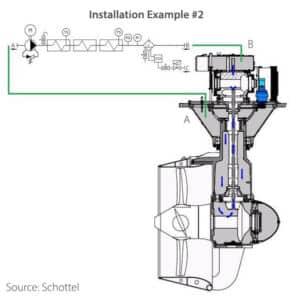

CJC® Thruster Filter for filtration and maintenance of gear oil

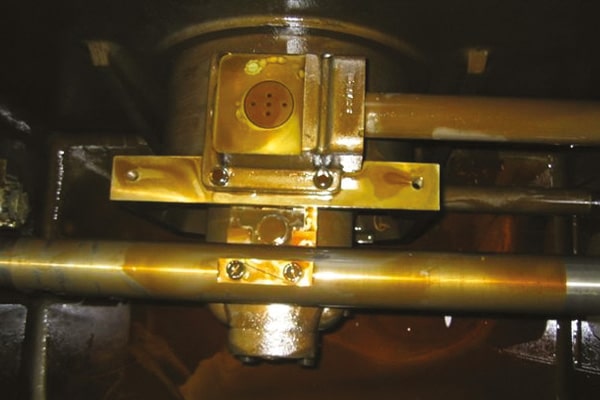

CJC® Thruster Filters for the filtration, dewatering and care of gear oil ensure consistently dry and clean lubricant. Achieve the highest level of protection for your oil filling and thruster quickly, long-lasting and cost-effectively.

Contact your maritime technical salesperson now

Let’s talk about your thruster, your gear oil and the specific challenges. We filter every gear oil. It does not matter whether you use mineral oil or biodegradable lubricant. Together with you, we maximize the service life of oil filling and thruster.

Receive a personal consultation and a non-binding offer about a CJC® thruster filter for the efficient care and filtration of gear oil.

Write or call me.

That say our customers

“Only with the CJC® Thruster Filter could the gear oil finally be dried satisfactorily. Without CJC®, we would have had to change the 1,500 litres of gear oil soon. By avoiding the oil change, we were able to save 4,890 EUR (3.26 EUR/litre) – an important contribution not only in terms of budget, but also in terms of resource conservation. The excellent results convinced us, so that we decided to purchase two identical CJC® Systems for our tugs “Bugsier-5” and “Bugsier-6”.

“The CJC® Thruster Filter allows us to remain the tug in operation for 6 months before its next technical shutdown. The results of the oil analyses are clear and clearly demonstrate the effectiveness of the CJC® Thruster Filter.”

„After having tested nearly every piece of water removing equipment on the market in order to solve our water and contamination problem, we decided for the CJC® Thruster Filter, because it was simply the best. The filters did the job to our greatest satisfaction, removing particles, water and other contamination. CJC® Thruster Filters for oil maintenance are a very good investment. The return of investment is very short.“