Minimize the water content in the oil even with stable emulsions

Desorbers from CJC®: Your solution for fast oil dewatering

Desorber for oil dewatering

CJC® Desorbers dewater and dry the oil or fluid in your machines quickly and cost-effectively. Whether hydraulic, gearbox or lubricating oil systems, whether mineral or synthetic base oils and whether the water is free, dissolved or emulsified in the oil, Desorber from CJC® remove the water from the oil or fluid of your machine independent from additives, viscosity and air content in the oil. Installed in the offline circuit, it ensures oil dewatering independent from the operation of the machine — even stable emulsions and bio-oils with a water content of up to 70% (700,000 ppm) can be dried. Optionally combined with a fine filter system that removes solid particles, oxidation residues and acids, it ensures maximum oil cleanliness in addition to the oil dewatering.

How to benefit from installing a CJC® Desorber on your machine

Keeping oils and fluids as dry as possible is the be-all and end-all for reliably functioning machines and stable processes.

Product Benefits — CJC® Desorber

Flexible all-rounder

CJC® Desorber dry any oil and fluid independent from the additive package and viscosity. Optionally with fine filter system for maximum oil cleanliness and oil sensors for integration into your condition monitoring system.

High efficiency

The CJC® Desorber removes free, emulsified and dissolved water from oils and fluids within a very short time – independently, continuously and highly efficiently. For absolutely dry oil.

Easy installation & maintenance

The CJC® Desorber is easy to install and operate. Due to the efficient oil dewatering, the operation without personnel requirements and the low maintenance intensity, it pay-back within the first year.

Economical & ecological

Depth filter made of 100% natural fibres – 0% plastic and 0% metals. High absorption capacities and thus long filter service life ensure excellent price-performance of the CJC® Desorber-Filter-Kombi-Units.

Areas of application — CJC® Desorber

In the paper, steel, plastic moulding and metal working industry just as in maritime applications exists environment and proccess related a high risk for water ingress in the oil systems.

Application segments

Fluids

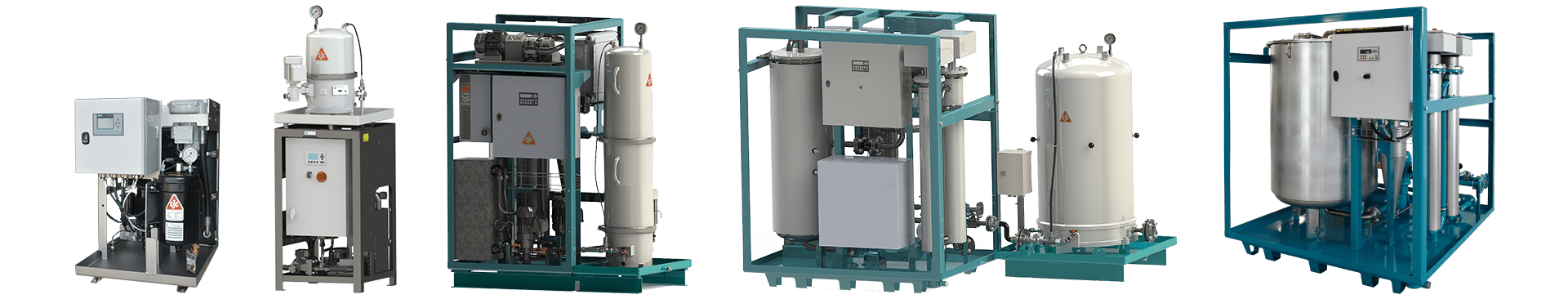

Sizes variants — CJC® Desorber for dewatering

… and combined with depth filter for oil care

The integrated CJC® Depth Filter Inserts

Separation capacity:

- Solid particles (wear and impurities)

- Water – free and dissolved

- Oil degradation products and oxidation residues (Varnish, oil sludge)

- Acids

Type of filtration:

- Depth filter with extremely high recording capacity

Inner surface:

- 120—150 m² per gram

- The largest depth filter insert has an internal surface of > 2,066 ha = > 2,894 football fields

- The smallest depth filter insert has an inner surface of > 5 ha = > 7 football fields

Due to the modular design, the number of various depth filter inserts and thus the holding capacity can be adapted to the individual dirt input.

Volume:

- The largest depth filter insert has a volume of > 504 Litres

- The smallest depth filter insert has a volume of > 1.5 Litres

Filtration degree:

- 3 µm absolute, retention rate down to 1 µm (Micrometer)

Filter material:

- 100% natural fibres – meets the requirements of the Circular Economy Act

For oils and fluids that tend to acidify very quickly, an additional filter material may be used, which increases neutralization against acids many times over.

Customer cases

Find out in our application studies how operators benefit from installing a CJC® Desorber

“I am completely satisfied with the investment. Oil drying takes place very quickly and without machine downtime. Thus, we keep the production stable, have time to look for the failure cause, avoid the oil change and waste oil disposal, and maintain the oil quality.”

“The Desorber works excellently in this application. I was impressed by the results and surprised how efficiently the Desorber dewatered the oil. The Desorber is easy to operate and is low-maintenance.”

“The CJC® Desorber allows us to operate the tug boat until the regular inspection in the dry dock in 6 months. The oil analysis results speak for themselves and substantiate the efficiency of the Desorber.”

“It was only with the Desorber that the gear oil could finally be dried satisfactorily. Without CJC®, we would have had to change the 1,500 litres of gear oil soon. By avoiding the oil change, we were able to save EUR 4,890 (EUR 3.26/litre) – an important contribution not only in terms of budget but also in terms of resource savings. The excellent results convinced us, so we decided to purchase two identical Desorbers for our tug boats, “Bugsier 5” and “Bugsier 6”.

“The Desorber is ideal for such operations because it works continuously while the vessel is at sea. The results are very satisfactory. The Desorber works very well and continues to reduce the water content.”

Contact your regional salesperson now

Let us start a conversation About your machine, your oil and the specific challenges. We dry any oil or fluid – even stable emulsions with a water content of up to 70%. Together with you, we maximize the service life of your lubricant and oil-lubricated components.

Receive a personal consultation and a non-binding offer for a CJC® Desorber for efficient oil dewatering and, optionally for oil cleaning.

Write or call us.