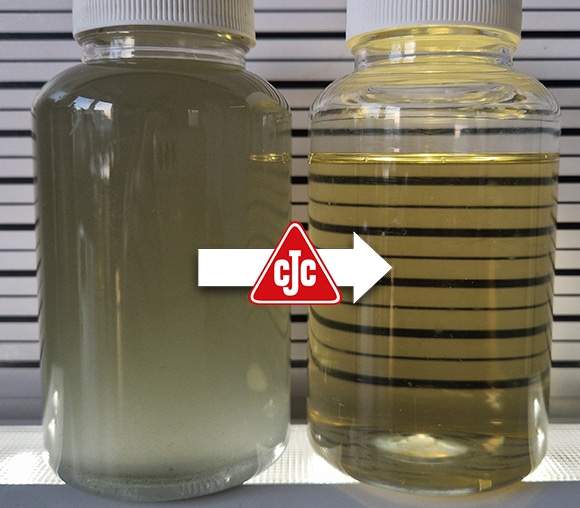

Maximize the service life of your cooling lubricants and tools

Cooling lubricant filters from CJC®: Your solution for the highest coolant purity within a very short time

Cooling lubricant filter

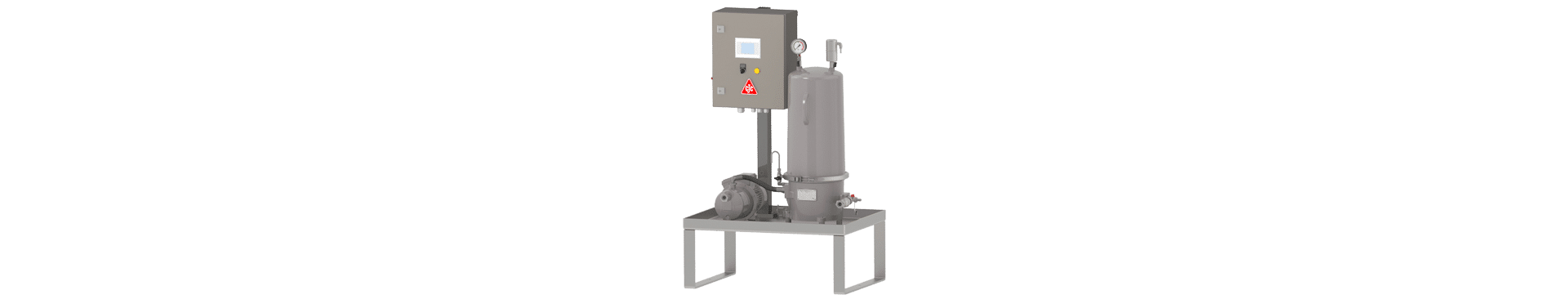

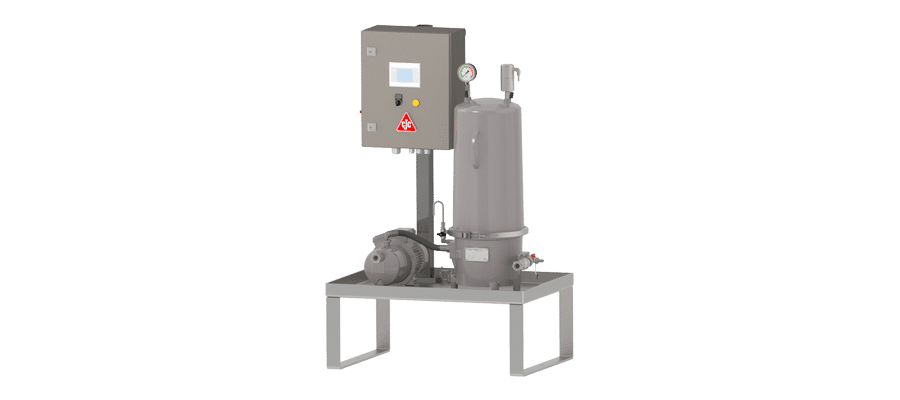

Cooling lubricant filters from CJC® clean and maintain your cooling lubricant quickly and cost-effectively. Whether machining centres or individual machine tools, whether central supply or small tank, whether aqueous or non-aqueous cooling lubricant, CJC® cooling lubricant filters are precisely configurable for your application. Installed in the offline circuit or on the IBC tank, they ensure maximum cooling lubricant cleanliness regardless of the process. They remove metallic chips, fine rod abrasion, sticky deposits, metal salts, foreign oils, greases and/or water — even microbial infestation — efficiently and reliably.

How you benefit from a CJC® Cooling Lubricant Filter

Product Advantages — CJC® Cooling Lubricant Filter

Perfectly fitting solution

Flexibly adaptable for every tank size & each lubricant – modularly configurable for optimum performance. Optionally with sensors for integration into your condition monitoring system.

Maximum coolant purity

Fast & reliable cleaning: Removes contaminants continuously, process-independently & highly efficiently. Maximizes the service life of cooling lubricant & tools.

Economical & ecological

Depth filter made of 100 % natural fibers – without plastic, metals and chemicals. High absorption capacities ensure long filter service lives and excellent value for money.

Simple installation & care

As an off-line filter or for recovery at the IBC tank – can be changed independet from machine operation. Low-maintenance, robust & durable for reliable use.

Product Features— CJC® Cooling Lubricant Filter

For cooling lubricant treatment, we customize your CJC® Cooling Lubricant Filter to suit your individual application. The cooling lubricant can be cleaned and, if necessary, dried in one or more stages:

1st stage:

Fluid care by means of fine and depth filtration for the removal of:

-

- Metal chips and fine abrasion particles

- Deposits and metal salts

- Tramp oils and greases

- Microorganisms

- Optional: Water (non-aqueous cooling lubricant)

2nd stagewith a lot of water in the non-aqueous cooling lubricant

Option a) Water separation using desorber technology

Application:

- Mineral oils and synthetic fluids with a poor water separation capacity (> 20 minutes)

- Up to ISO VG 1000 @ 40°C

- Emulsions with a water content of up to 70% or 700,000 ppm

Option b) Water separation by means of coalescing

Application:

- Mineral oils and synthetic fluids with a good water separation capacity (< 20 minutes)

- Up to ISO VG 460 @ 40°C

Equipment:

Standard:

- Pump unit for installation in the offline circuit or on the IBC tank

- Electrical control (incl. motor protection switch and shunt)

- Saturation monitoring of the depth filter insert

- Automatic bleeding and venting valve for quick filter insert replacement

- Leakage sensor as a warning system in the event of leakage of cooling lubricant

- Non-return valve to avoid a return flow

- Sampling point for analysis

- Raised base plate for better handlingoptional with sensors for condition monitoring

The integrated CJC® Depth Filter Insert

Separation capacity:

- Solid particles (wear and impurities)

- Water – free and dissolved

- Oil degradation products and oxidation residues (Varnish, oil sludge)

- Acids

Type of filtration:

- Depth filter with extremely high recording capacity

Inner surface:

- 120—150 m² per gram

- The largest depth filter insert has an internal surface of > 2,066 ha = > 2,894 football fields

- The smallest depth filter insert has an inner surface of > 5 ha = > 7 football fields

Due to the modular design, the number of various depth filter inserts and thus the holding capacity can be adapted to the individual dirt input.

Volume:

- The largest depth filter insert has a volume of > 504 Litres

- The smallest depth filter insert has a volume of > 1.5 Litres

Filtration degree:

- 3 µm absolute, retention rate down to 1 µm (Micrometer)

Filter material:

- 100% natural fibres – meets the requirements of the Circular Economy Act

In the case of oils and fluids that quickly have a high acid content, we may add an additional filter material that neutralizes acids to a greater extent.

Contact your regional salesperson now

Do you have any questions about our cooling lubricant filters, rental-purchase options or cleaning and maintaining cooling lubricants? Is your cooling lubricant exceptionally heavily loaded and you do not know whether it can be cleaned cost-effectively? Our regional contacts will be happy to help you find out exactly that. Just call or e-mail.