Condition Monitoring Unit — Oil Condition Sensors

The Condition Monitoring Unit CMU with oil condition sensors and particle counter for monitoring of oil and machine condition is a premium-monitoring-solution. The numerous oil sensors offer a high data density, deliver exact oil condition values in real time, deliver reliable data and ensure the highest oil cleanliness levels. The CJC® CMU installed with a CJC® Oil Care System in an off-line circuit is the optimum combination for proactive and condition-based maintenance.

ADVANTAGES DUE TO CONDITION MONITORING

- Maximum wear protection and maximum oil service life through efficient oil care and continuous monitoring of the oil and machine condition — always clean and dry oil

- Increase machine reliability and improve process reliability

- Data logging in real time as an early alert system for application- and machine-specific limit values

- Individual and transparent data interpretation makes it possible to detect harmful influences and wear on components as early as possible, to minimize their effects and to find the cause

- Plannable, calculable maintenance instead of unplanned, cost-intensive failures

- Modular implementation of the oil condition sensors enables exact configuration to the specific operating conditions

- High-quality oil condition sensors ensure accurate and reliable values

- Online-Monitoring as Best-Practice-Method optimizes the oil analysis program and management

- Quickly generate high savings and accelerate the return on investment of the machine

FEATURES — CJC® CONDITION MONITORING UNIT

In addition to the CJC® Oil Contamination Monitor OCM15 for monitoring the particle content in the oil, the integrated CJC® sensor technology also includes numerous interfaces for the modular implementation of further oil condition sensors and thus offers the possibility for the highest data density and precise interpretation of the oil and machine condition.

The pump-unit allows a separate oil circuit, so that volume flow and low-pressure conditions can be optimal and individual adjusted to sensor-packages. Independent from viscosity, air entrainment and operation of the machine, exact oil condition values are permanently measured. The CJC® CMU is installed upstream of the CJC® Oil Care System (dirty side). Quick and easy retrofit is possible.

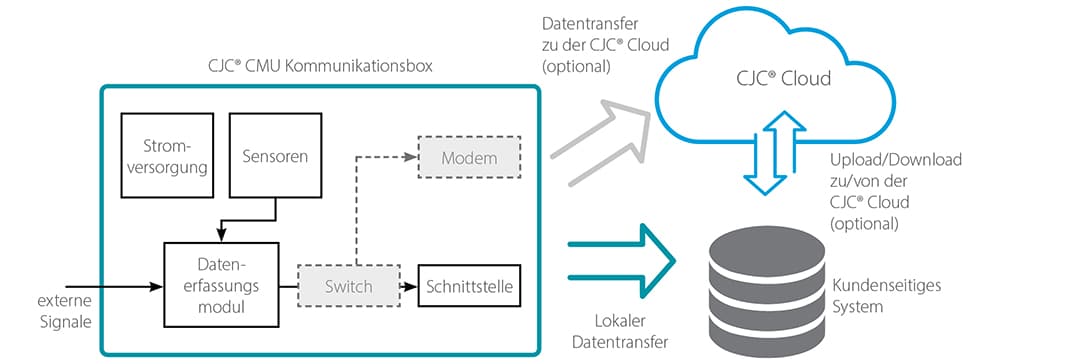

DATATRANSFER & MONITORING

For local data transfer, the CJC® CMU offers numerous options for data logging. Optional sensor data can be transferred into thecloud-application CJC® T²render.

| Oil condition sensors | ||||||||

|---|---|---|---|---|---|---|---|---|

| CJC® Condition Monitoring Unit | External sensors *) | |||||||

| OCM | OMT | OQM | PT100 | PT in |

PT out |

ODM | Input | |

| Particles 4—250 µm (according to ISO 4406) |

✔ | |||||||

| Oil moisture | ✔ | |||||||

| Oxidation parameters | ✔ | |||||||

| Oil temperature (°C) | ✔ | ✔ | ✔ | |||||

| Pressure, filter inlet (bar) |

✔ | |||||||

| Pressure, filter outlet(bar) | ✔ | |||||||

| Wear debris 40—1.000 µm(ferrous/non-ferrous) | ✔ | |||||||

| Oil care and analysis Operation (on/off) |

✔ | |||||||

| Maschine load (0—100 %) |

✔ | |||||||