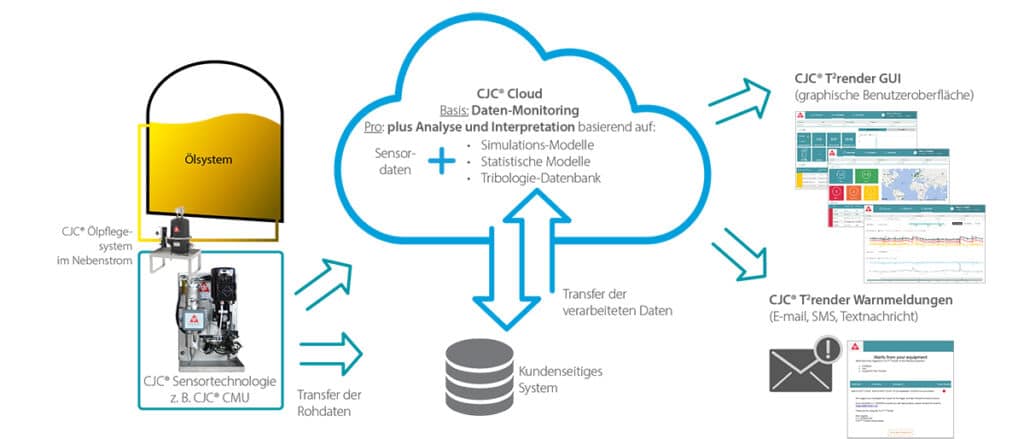

Cloud-application for oil sensors — automatized evaluation of the sensor data

The cloud-application for oil sensors enables automized evaluation of oil sensors — machine-specific and precise. Installing the CJC® Sensor Technology in combination with a CJC® Oil Care System in an offline circuit is required. Further information see:

• CJC® Condition Monitoring Unit CMU

• CJC® Oil Contamination Monitor OCM15

The CJC® OCM15 and the CJC® CMU with modular implementable sensors offer the data transfer interfaces to the cloud-application. Two versions of the cloud-based application CJC® T2render are available:

Cloud-application for oil sensors — CJC® T2render BASIC

The cloud-application as basic version enables the monitoring of the sensor data in real-time and performs as an early alert system. It sends warnings to the operator as soon as the sensors measure custom-specified limit values.

Cloud-application for oil sensors — CJC® T2render PRO

The cloud application as pro version enables the automized evaluation of the sensor data based on high-developed algorithms and the machine-specific configuration. The comprehensive data of the numerous sensors (high data density) deliver precise and valuable information about oil condition and machine condition.

It enables earliest possible warnings as soon as the oil and/or machine condition differ from the initial custom-defined „normal condition“. The unique intelligence based on high-developed algorithms simplifies the manual and complex data interpretation, considering all data of each sensor.

ADVANTAGES DUE TO ONLINE-MONITORING OF OIL CONDITION

The cloud application CJC® T2render is especially developed for CJC® Oil Care System with sensor technology and is the optimal combination for proactive and condition-based maintenance:

- The CJC® Oil Care System achieves permanently highest oil cleanliness levels due to efficient and continuous fine and depth filtration in the off-line circuit (24/7) — at all times, clean and dry oil:

- Maximum wear protection

- Extended lifetime for oil, components and machine

- Increased machine reliability and process stability

- High savings and accelerated return on investment

- The CJC® sensor technology and the cloud-application CJC® T2render are essential the optimization of the oil analysis program and management due to predictive maintenance methods:

- Permanently high oil cleanliness levels

- Reduction of administrative expenditure

- Early alert and wear warning system

The earlier wear in the earliest stages is detected, the earlier you have the possibility to take action, the longer the lifetime of components and machine and the more plannable, calculable and cost-efficient are maintenance measures.

FUNCTIONS — CJC® CLOUD APPLICATION

The basic and pro version of the cloud application CJC® T2render offer different features and service levels:

| Functions | CJC®T²render cloud application BASIC | CJC®T²render Cloud Application PRO |

| Storage of sensor data – in the CJC® Cloud and up to 30 days offline as a backup |

✔ | ✔ |

| Web-based dashboard, monitoring of sensor data in real-time, history, logbook | ✔ | ✔ |

| API interface for the transfer of raw data and treated sensor data | ✔ | ✔ |

| Performance-Monitoring of proactive oil care measures to ensure the highest oil cleanliness | ✔ | ✔ |

| Specification of limit values and individual configuration of the sensors for warnings |

✔ | ✔ |

| Technical support for installation | ✔ | ✔ |

| Configuration of the CJC® T2render Cloud and technical support during commissioning | ✔ | ✔ |

| Automatic analysis and precise interpretation of all sensor data as well as conversion into an oil and machine condition. | ✔ | |

| Detection of already slightest deviations from the pre-defined “normal condition” |

✔ | |

| Automatic and valid warnings uniquely adapted to each oil system with appointed direct cause(s) | ✔ | |

| Technical support during the whole period | ✔ | |

| Yearly review of system condition and retraining requirements | ✔ | |

| Recalibration of sensors | ✔ |